Timber Frame Homes and Wood Trusses

Building systems: Timber Frame and Wood Truss Solutions

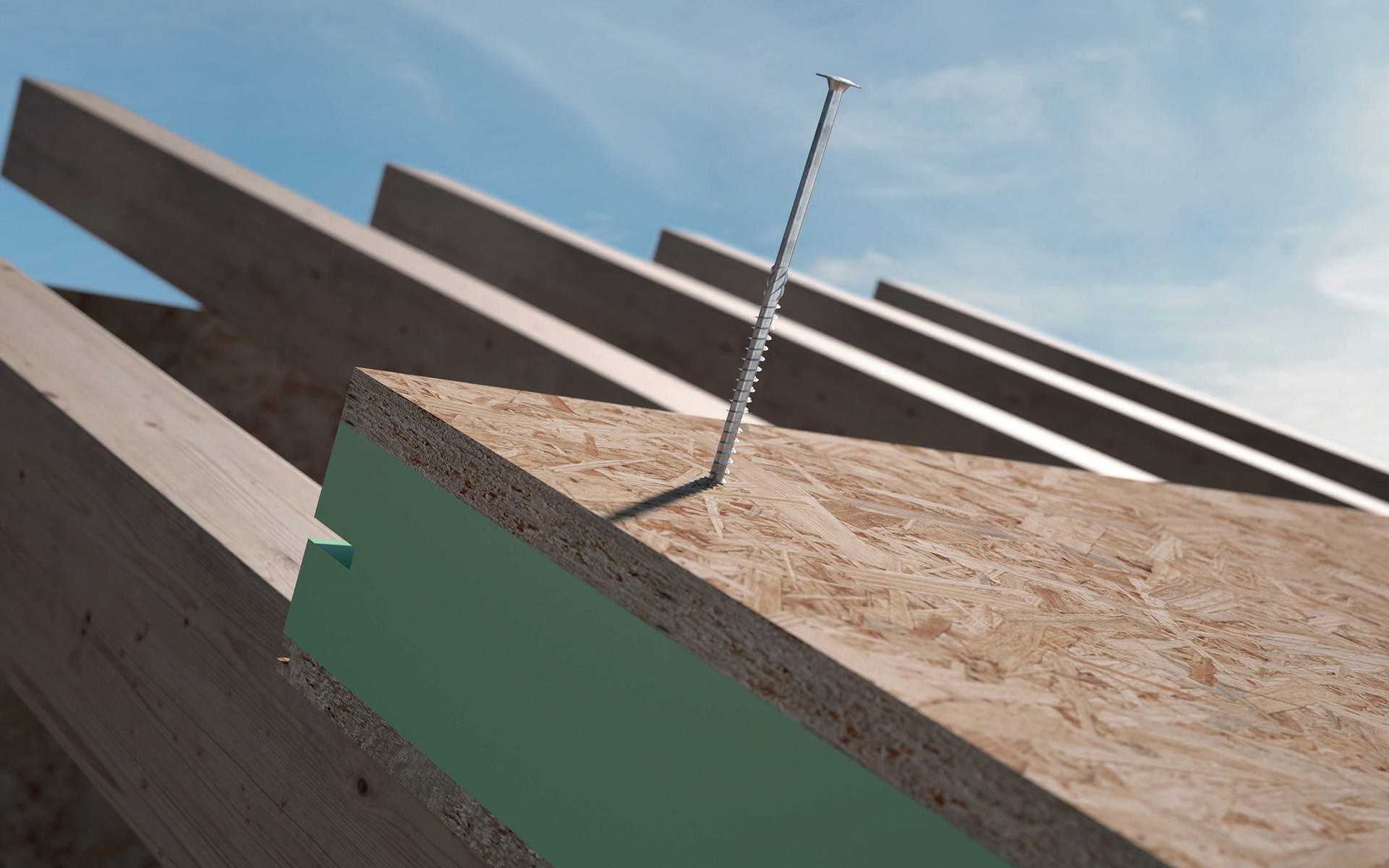

Timber frame homes and wood trusses are fundamental components in modern light-weight construction, providing both aesthetic appeal and structural integrity. Timber frame construction systems utilize load-bearing walls made from a frame of struts filled with insulating material and stiffened with OSB panels.

This method, characterized by its lightness and quick build time, saves both time and resources compared to other construction systems. Over the years, these systems have evolved, incorporating advanced materials and techniques to enhance their performance and sustainability.

Timber Frame houses and buildings: a sustainable choice

Timber frame houses are renowned for their sustainability and efficiency construction method, which includes platform frame, balloon frame, semi-balloon, and truss-framed systems, has been widely adopted across the Anglo-Saxon world since the 19th century.

These systems are celebrated for their simplicity, cost-effectiveness, and for the use of more sustainable materials, such as solid timber, I-joists, and OSB or plywood: at Rothoblaas we know this sector well, thanks to a network of expert customers, and we have been spreading awareness of timber frame for years, as you can read here: The Timber Frame construction system.

This traditional approach continues to be favored for its proven effectiveness and adaptability to various architectural requirements, but he is not the only protagonist of construction in the English-speaking world.

Wood Roof Trusses: structural integrity and design

Wood roof trusses are structural frameworks made from wood, designed to support and stabilize roofs or floors. They consist of multiple wooden elements arranged in triangular units, which efficiently distribute loads and provide stability.

Wood trusses are mostly prefabricated, ensuring precision and consistency, and are widely used in residential, commercial, and industrial construction. Engineered wood trusses, designed to support the roof's load, offer several advantages, including precision in design, ease of installation, and enhanced load-bearing capacity.

Prefabricated wood trusses are designed to meet specific building codes and standards, ensuring safety and reliability in construction.

What are the key points in choosing screws for timber and wooden trusses?

Truss wood screws: head pull-through capacity for suspended and supported applications in Wood Trusses.

Truss wood screws need to have an extra strong head pull-through capacity for the connections from and to the truss itself, whether it is a SIP or sandwich panel to be connected to the trusses from the top, or elements in suspended applications below the trusses. These screws must be designed with extra-large flange heads, to provide enhanced surface area for higher capacity, better grip and general stability of the Wood Trusses. This design distributes the load pressure evenly, ensuring secure and strong connections in wood trusses. The screws maintain their hold under dynamic loads, making them ideal for applications requiring durable fastening.

The role of softwoods in Timber Frame construction

Softwoods, such as pine and spruce, are the most common species used in timber frame construction due to their availability, workability, and favorable strength-to-weight ratio. These woods are often chosen for their ability to withstand various environmental conditions and their compatibility with different fastening systems. The use of softwoods in timber frames contributes to the overall sustainability of the construction, as these materials are renewable and can be sourced from sustainably managed forests.

Advanced building with SIP Panels and Multi-Ply screws

Structural Insulated Panels (SIP) and multi-ply screws represent advanced solutions in timber frame construction. SIP panels consist of an insulating foam core sandwiched between two structural facings, typically OSB.

These panels offer excellent thermal insulation, structural strength, and ease of installation. Multi-ply screws, designed to connect multiple layers of timber or composite materials, provide enhanced load distribution and stability. They are widely used in North America and Commonwealth countries as a more sustainable, less laborious and removable alternative to adhesives for laminated timber. Together, SIP panels and multi-ply screws improve the efficiency and performance of timber frame buildings.

TBS new lines for USA, UK, Australia, New Zealand and North Europe: TBS MAX, TBS SOFTWOOD, and TBS FRAME

The new TBS lines cater to the specific needs of timber frame construction in the USA, UK, Austalia, New Zealand and Northern Europe. TBS MAX offers robust fastening solutions for heavy timber applications, while TBS SOFTWOOD focuses on facilitating initial grip and subsequent pull-through in soft woods. Lastly, TBS FRAME includes a variety of sizes specifically designed for modern timber frame construction.

The TBS MAX line is engineered to provide exceptional strength and durability for heavy timber applications. These fasteners are designed to handle significant loads and stresses, making them ideal for large-scale timber constructions such as commercial buildings and complex architectural projects. TBS MAX extra-large washer head and optimized thread pitch, provide the maximum axial resistance. The XL washer head improves the head pull-through capacity, allowing for strong massive applications like ribbed floors, for secure suspended applications and roofing connections to withstand strong wind pressure forces.

TBS FRAME is a specialized flat flange head screw designed for timber construction, offering excellent tightening capacity without adding thickness to the wooden surface. This feature allows for the seamless fixing of plates on the same element without interference. The screw's short, fixed-length thread is optimized for fastening multi-layer elements, such as in lightweight frame construction, making it ideal the ultimate multi-ply screw for use with multi-ply timber.

The TBS SOFTWOOD line is specifically developed to get the most softwood timber applications. These fasteners are designed to work effectively with the characteristics of softwoods such as pine and spruce, providing optimal holding power with an increased and fast thread, and reducing the risk of wood damage with its SAW tip.

Fast thread pitch, longer thread and large head makes it the ideal choice in everyday robust softwood applications.

By leveraging these new TBS screws, builders and engineers can achieve superior results in timber frame construction, ensuring both the strength and longevity of their projects, and find new allies for optimizing wood roof trusses resistance, both in traditional and contemporary projects.

TBS lines will be available in September: don’t miss the chance, know everything you need about them and place your order, check the technical data sheets here.

All rights reserved

Technical Details

- Companies:

- ROTHOBLAAS

- Country:

- Any

- Products:

- TBS MAX TBS SOFTWOOD TBS FRAME