Post and Beam

How to choose connections

The term Post and Beam today refers to a framed (post and beam) structure made of engineered timber (CLT, Glulam, LVL, etc.). The floors are normally made of timber-based panels, while the lateral stability of the building is normally entrusted to a bracing system (core, inclined rods or walls).

The main difference compared to the Timber Frame (or light-frame) system lies in the material and resulting strength of the structure. But Post and Beam is simply a modern adaptation of the world’s oldest building system – the trilithic system – consisting of a stone lintel supported by two columns, reinterpreted using engineered timber and similarly inherited by today’s concrete frame structures. So, if it's that ancient, how can it be innovative? In many ways in fact, from the choice of materials to the connections.

From gazebo to multi-storey

The Post and Beam technique is highly versatile, suitable for various applications ranging from light outdoor structures to more complex, structurally demanding projects. Today, multi-storey buildings can be constructed in timber with wide column spacing and spans that, up until a few years ago, were only achievable using reinforced concrete. Unlike the latter, however, using timber equates to faster construction and, above all, greater sustainability. According to data from a recent study, every square metre of timber construction saves an average of about 74 kg of CO2 compared to concrete. Moreover, the impact on water consumption is much lower, with 5 cubic metres of water saved for every square metre built. Lastly, using timber as a structural material drastically reduces the amount of waste produced, with over 158 kg less per square metre.

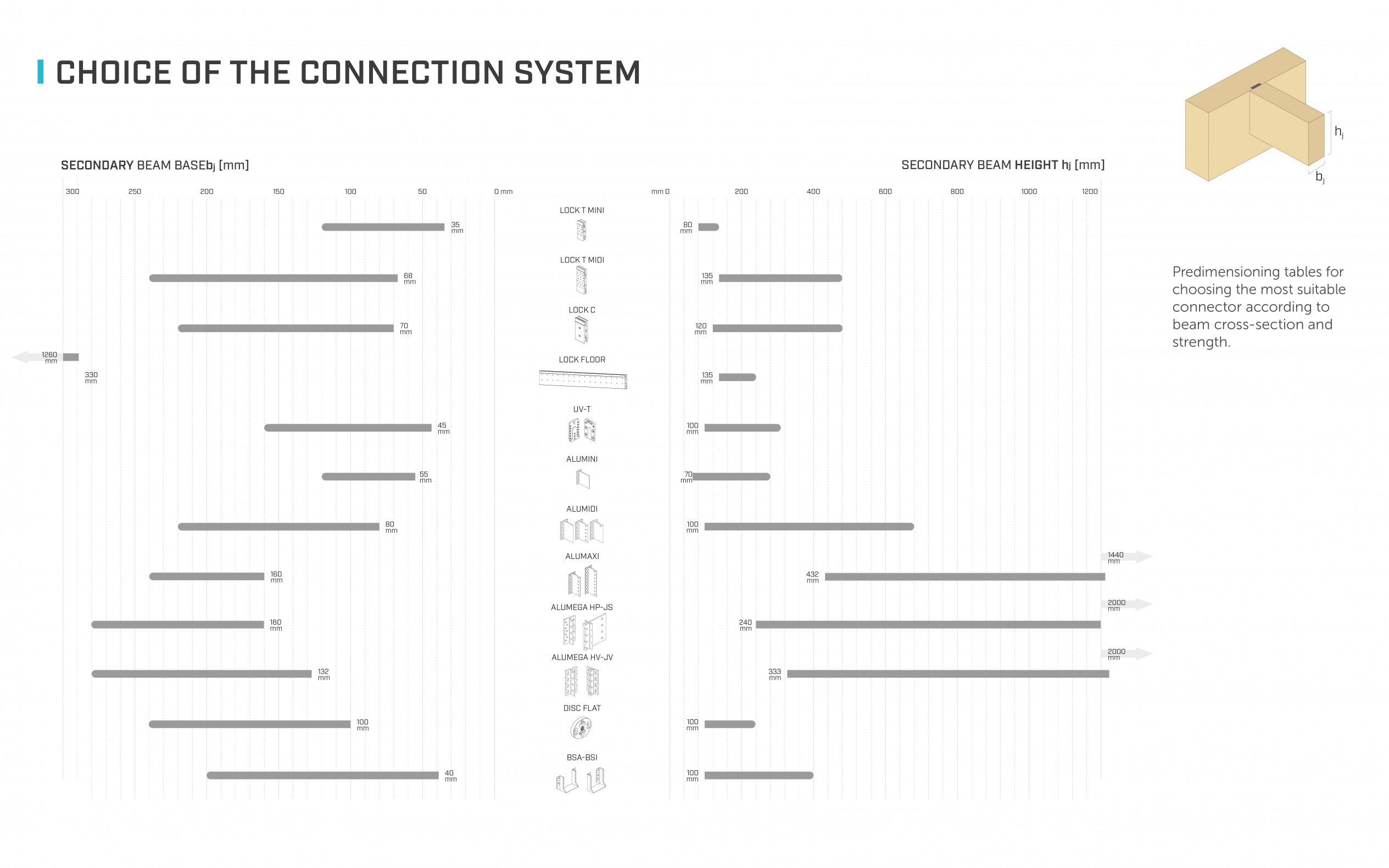

However, aside from engineered timber, every type of structure requires proportionate connections. The wide range of Rothoblaas jointing systems effectively meets various design needs. Below is a table extracted from the new Plates and connectors for timber catalogue, indicating the most suitable connectors depending on the beam section.

How to choose the right connector for post-and-beam structures?

To choose the connector most suited to each Post-and-Beam project, Rothoblaas offers two essential tools:

1) The "LOCK CONNECTOR SELECTION AND GUIDE TO DURABILITY", designed to help identify the best concealed solutions based on the specific installation conditions. Factors such as exposure, humidity, pollution, proximity to the sea, the timber’s pH and service class are all considered. For more information, click here.

2) CONNECTOR SELECTION GUIDE BASED ON PROJECT TYPE:

Developed as part of the European Build-in-Wood project, this tool is part of the more comprehensive guide developed by the Build-in-Wood network, designed to assist in selecting the most appropriate structural and façade system components, ensuring the right solutions for any timber project.

Each section is dedicated to a different type of component, focusing on maximising the use of timber and bio-based materials in the evolving European construction landscape.

The solutions meticulously designed and calculated by members of the Build-in-Wood project include the “Connector Matrix”, developed by the Rothoblaas research and development team to help select the most suitable connector for post and beam systems, based on the project’s intended use and scale.

Try it here: (https://www.rothoblaas.com/ftp/BiW_SYSTEM%20AND%20CONNECTION%20MATRIX_EN.pdf)

These tools guarantee the selection of functional, durable and technologically advanced connectors that precisely meet the specific needs of each Post-and-Beam project.

Hybrid structures

In a Post and Beam structure, while the columns don't necessarily need to be in timber, the timber beams can be connected to structural elements made of various materials, including timber, steel or concrete. The Rothoblaas range includes special solutions catering to this requirement too.

Beam connections must mainly withstand gravitational loads (Fv in the image below). The tested and certified strengths in all directions are a guarantee of structural robustness in the event of exceptional events (shocks, explosions, hurricanes, earthquakes). This contributes to the structural strength of the building, ensuring greater safety and resistance. Below is a table to help select the most suitable connector based on the required strength.

Installation techniques and prefabrication

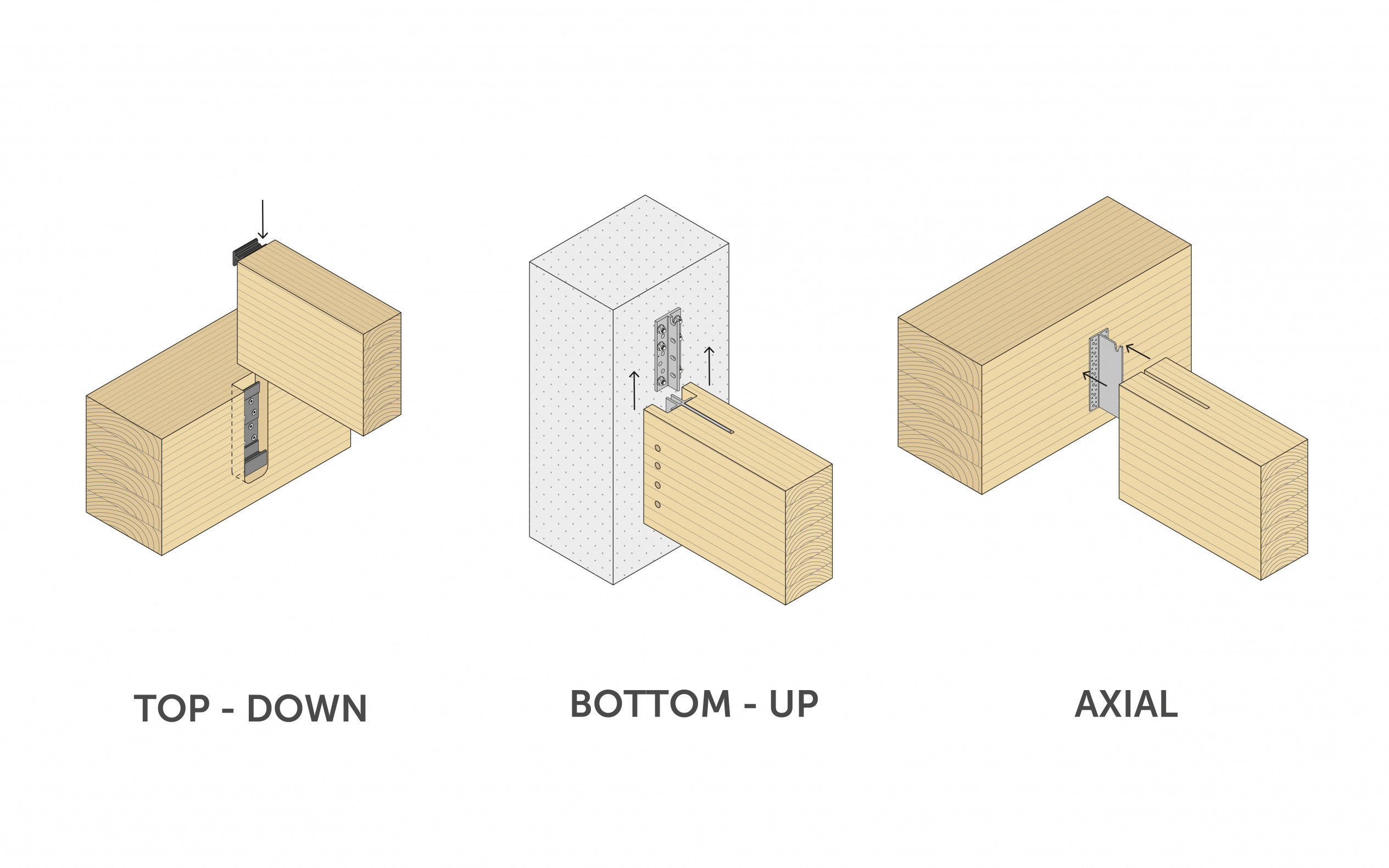

In a Post and Beam structure, connections must offer static strength and structural robustness while also ensuring good aesthetics and flexible installation. Additionally, important features include the potential for prefabrication and demountability, making it crucial to select the most suitable connection. Each construction site has its own logistical requirements that impose different construction sequences. For example, by choosing the most suitable fastening mode, it is possible to install the beam in different ways.

For instance, the LOCK series requires Top-Down fastening. ALUMINI, ALUMIDI and ALUMAXI are commonly installed Bottom-Up, although they could also be installed Top-Down or perpendicularly (Axial), and even ALUMEGA can be installed using all three techniques.

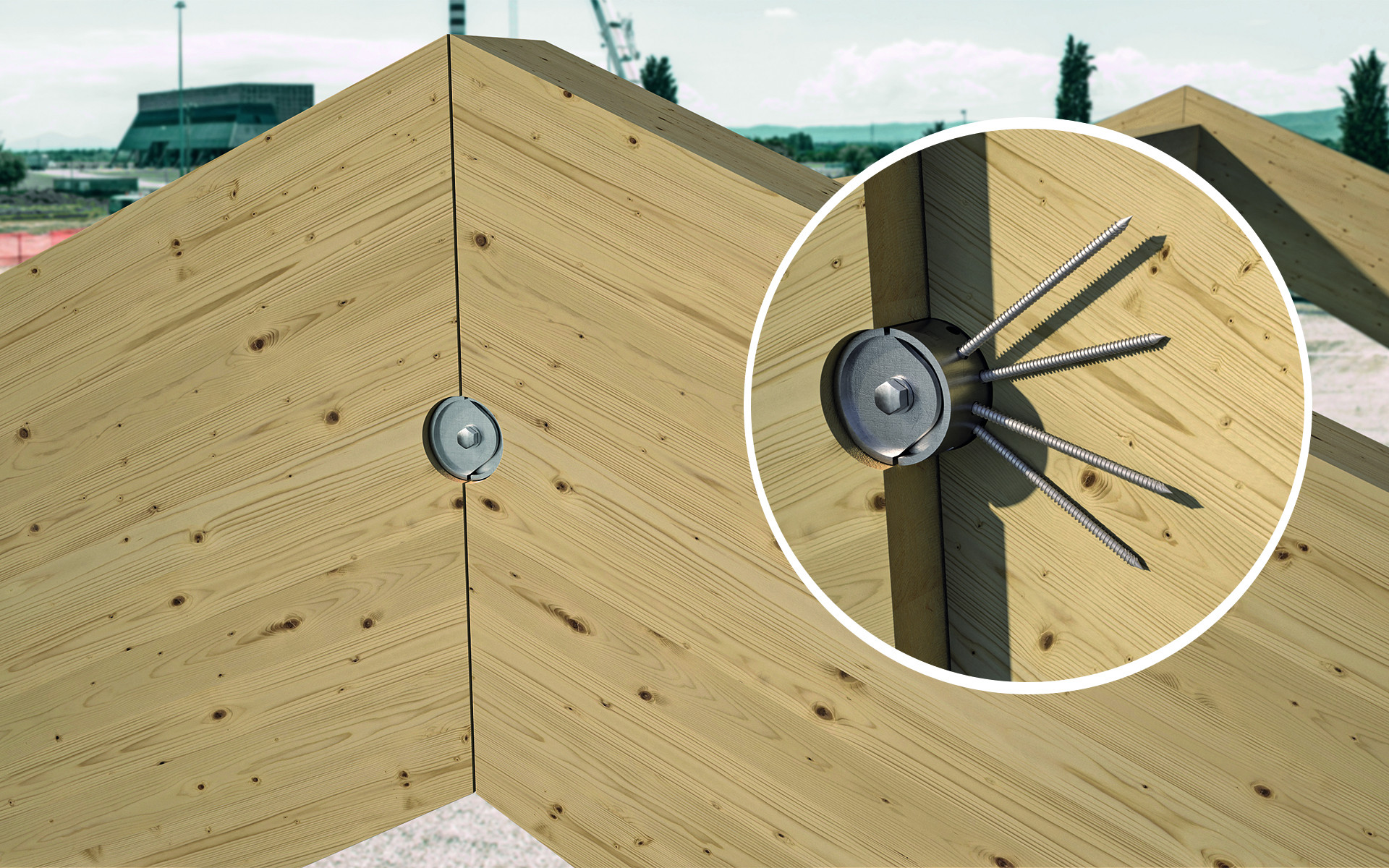

Some connection systems can be partially or fully prefabricated in the factory, pre-installing the connectors on the beams and columns, thus working in a controlled environment not subject to weather events. Then, on site, it is sufficient to integrate the connection with just a few connectors, minimising the risk of errors. Prefabrication often also means disassembly: what requires little effort on site to be assembled, will require little time in the future to be disassembled for building modification/expansion needs, or for demolition at the end of its useful life. Several Rothoblaas connectors have been designed with the prefabrication of Post and Beam structures specifically in mind, including the ALU and LOCK, UV-T and DISC FLAT series, along with the RADIAL demountable connector.

Browse the new plates catalogue now to make sure you choose the right connections for your project, or contact your local agent.

All rights reserved

Technical Details

- Country:

- Any

- Products:

- LOCK T MINI LOCK T MIDI LOCK C LOCK FLOOR UV T ALUMINI ALUMIDI ALUMAXI ALUMEGA DISC FLAT BSA BSI