Passive House and Blower Door Test

How Rothoblaas membranes and sealing tapes ensured energy efficiency for a Passive House in Korea:

What is a Passive House?

The Blower Door Test: Checking airtightness in a Passive House

Membranes and tapes: Why are they so important?

The results of the Blower Door Test in Korea

The importance of energy efficiency for the future of timber construction

Plantree, a leading builder of passive homes, took on the challenge of ensuring that a new housing project in Korea met the strict requirements of the Passive House standard. To do so, the company opted for Rothoblaas’ range of airtightness solutions, incorporating membranes and sealing tapes designed to optimise the energy efficiency of timber buildings. To check whether these solutions were able to satisfy the requested airtightness levels, the system was tested by applying the rigorous Blower Door Test, key in determining the efficacy of the building envelope. The results showed a significant improvement in performance.

So, what exactly are the requirements of a Passive House? And what is the Blower Door Test?

What is a Passive House?

A Passive House is an international construction standard developed by the Passive House Institute (PHI) in Darmstadt, Germany, in 1996, aimed at reducing the energy consumption of buildings by up to 90% compared to traditional homes. The basis of this standard is the optimisation of thermal insulation, door/windows efficiency and, above all, airtightness.

In order to be certified as such, a Passive House must satisfy a series of very strict criteria:

Heating demand: Must not exceed 15 kWh/m² per year.

Primary energy demand: Must be less than 120 kWh/m² per year, also considering energy for domestic hot water and electricity.

Airtightness: The building must maintain an airtightness such as not to exceed 0.6 air changes per hour (ACH) at a pressure of 50 Pascals.

Thermal comfort: Indoor temperatures must remain stable all year round, without exceeding 25°C for more than 10% of the hours in a given year

The Passive House Institute not only sets certification standards for buildings but also certifies specific components and solutions for the construction of passive homes. It also provides advanced tools like the Passive House Planning Package (PHPP), allowing architects and engineers to calculate and optimise a building's energy performance right from the earliest stages of design. These buildings not only drastically reduce the demand for energy, they also ensure stable indoor comfort year-round, maintaining ideal temperatures in both summer and winter.

The Blower Door Test: Checking airtightness in a Passive House

The Blower Door Test is a method designed to assess a building’s airtightness by measuring air leakage through joints, doors, windows and other components. Here’s how it's done:

Installation of the Blower Door: A calibrated fan is installed in one of the building’s main openings, normally an external door. The fan is installed on a flexible frame, which perfectly seals the opening. The other openings (windows, doors, fresh air intakes) are all closed.

Creation of a pressure difference: The fan generates a pressure difference between the inside and outside of the building, typically set at 50 Pascals. This simulates a moderate wind that pushes the air either in or out of the building.

Air flow measurement: Sensors connected to the fan measure the volume of air needed to maintain the pressure differential. The test determines how much air is needed to fill or empty the building, identifying the points where air leaks occur. The result is expressed in Air Changes per Hour (ACH), indicating the number of times that the air volume in the building is removed and replaced in an hour, for each cubic metre of living space.

Detection of air leaks: During the test, operators often use tools like thermal cameras or smoke detectors to visually identify air infiltration points. These tools allow for precise detection of critical areas such as joints, doors/windows or unsealed connections.

Comparison with the Passive House standard: To achieve Passive House certification, the air exchange rate must be below 0.6 ACH. Higher values indicate the need for additional measures to improve the building’s airtightness.

This test is crucial in ensuring the building is sufficiently airtight to prevent energy loss, maintain a stable indoor temperature and reduce heating and cooling costs.

Membranes and tapes: Why are they so important?

Airtightness is a crucial element in modern construction, particularly in timber buildings. Without proper sealing, warm indoor air can easily escape during the winter, while warm, humid air can easily infiltrate in the summer. This not only compromises the thermal comfort of whoever is inside but also significantly increases the amount of energy consumed for heating and cooling purposes.

In buildings without proper sealing systems, air leaks can account for up to 40% of total heat loss, even in well-insulated structures. The use of membranes and sealing tapes is therefore crucial in creating a continuous barrier against infiltrations.

These materials, applied along the building envelope, seal the joints between walls, windows, doors, ceilings and floors, preventing thermal bridges and energy loss.

Breathable membranes and sealing tapes stop the air from passing through the building envelope. This not only reduces heat loss but also significantly improves humidity control.

Effective humidity management prevents condensation and mould, enhancing the structure’s long-term durability.

The importance of these solutions is especially clear in timber construction, where a lack of airtightness can lead to structural damage due to the build-up of humidity.

An airtight building envelope, achieved through the use of membranes and sealing tapes, helps protect the timber from deformations caused by humidity cycles, improving the stability and durability of the building.

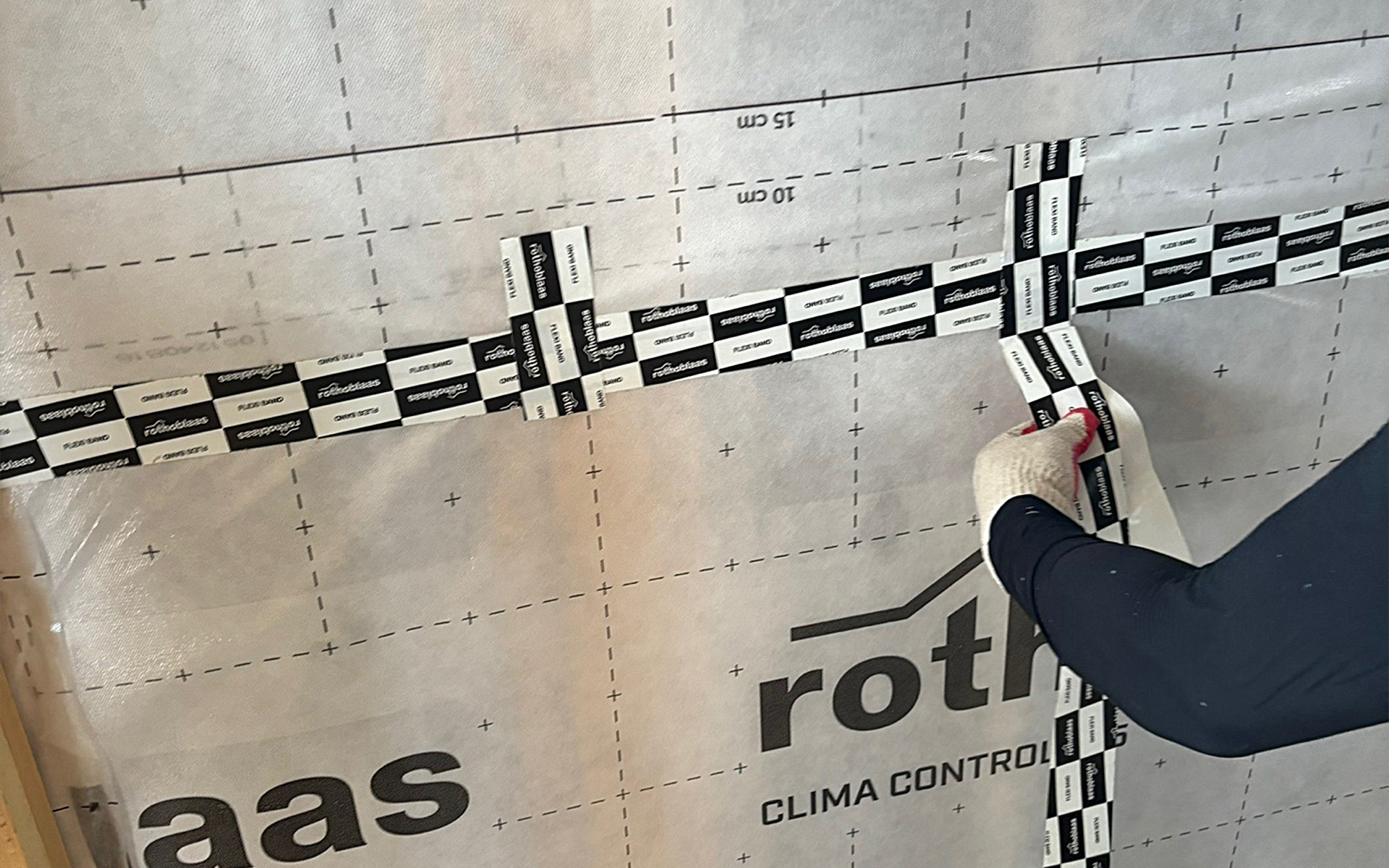

For this particular project in Korea, Rothoblaas supplied solutions including TRASPIR 150, TRASPIR 95, and CLIMA CONTROL 105 membranes, combined with FLEXI BAND tapes. These materials have proven highly effective in sealing timber structures, significantly reducing air leakage and optimising internal humidity management. This led to excellent results in the Blower Door Test, helping to achieve the airtightness required to meet Passive House standards.

The results in Korea

In the Korean project developed by Plantree, the selected Rothoblaas solutions were found to exceed expectations. During the Blower Door Test, the building achieved a value of 0.14 Air Changes per Hour, an excellent result confirming the airtightness of the building envelope. This result is one of the best of 2024, validating the effectiveness of Rothoblaas solutions and Plantree’s design for energy efficiency.

The importance of energy efficiency for the future of timber construction

Energy efficiency is a crucial topic for the future of construction. Regulations are imposing increasingly stringent standards, and the use of high-tech materials is essential in meeting these challenges.

Given the growing demand for sustainable buildings, the adoption of standards like Passive House is set to become increasingly common.

Plantree’s experience in Korea highlights how using the right airtightness solutions can be the key factor in determining whether a building is energy-consuming or energy-efficient.

Using Rothoblaas’ Passive House-certified membranes and sealing tapes makes it possible to achieve extremely high airtightness levels, contributing to energy savings and improving living comfort.

Energy efficiency is about more than just saving money: it is the future of building, and especially timber construction.

Investing in certified materials is key to achieving sustainable and long-lasting buildings:

Explore Rothoblaas’ full range of energy-efficiency solutions by visiting our dedicated page HERE, and see the Plantree tests on their YouTube channel HERE.

All rights reserved

Technical Details

- Companies:

- Plantree

- Country:

- Korea

- Products:

- TRASPIR 150 TRASPIR 95 CLIMA CONTROL 105 FLEXI BAND