Monolithic membranes vs. microporous membranes

When it comes to protecting timber buildings and other types of buildings, and managing moisture, choosing the right breathable membrane is crucial.

Two of the main types of membranes used in the construction sector are monolithic and microporous membranes.

In order to choose the best solution for each project, we need to explore the technical differences between these two technologies, with the support of a detailed guide on which solution is best suited for different construction needs.

How to choose the right membrane?

For the purpose of maintaining the properties of the product, it is important to select it taking into consideration the conditions it will have to withstand, from construction site to operation. Protecting it as much as possible is essential since the construction phase is a source of stress and accelerated ageing.

How is the durability of membranes affected?

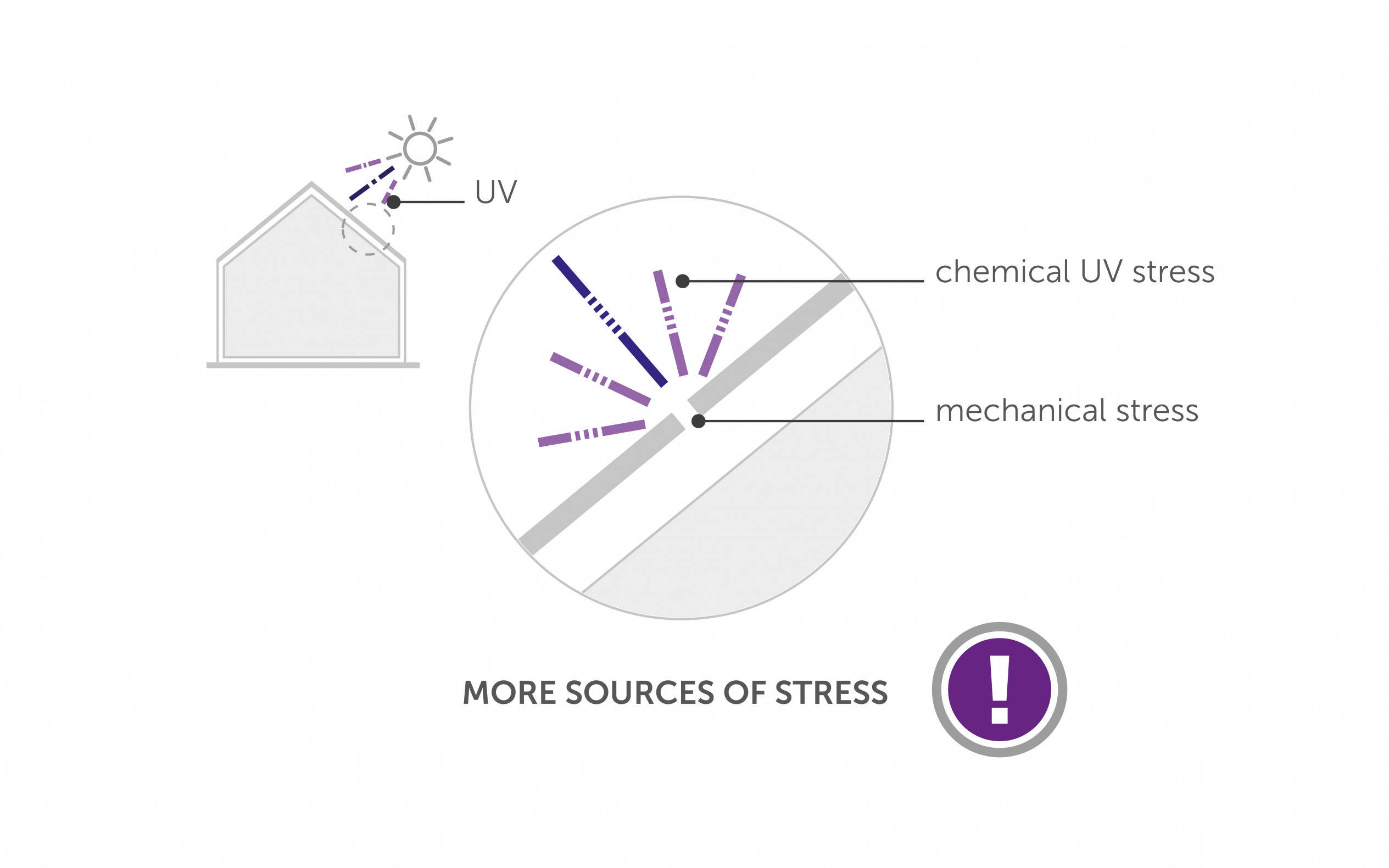

The durability of monolithic and microporous films is affected by structural differences, and by the sum of the sources of stress: temperature, UV exposure and pollutants.

Structural differences

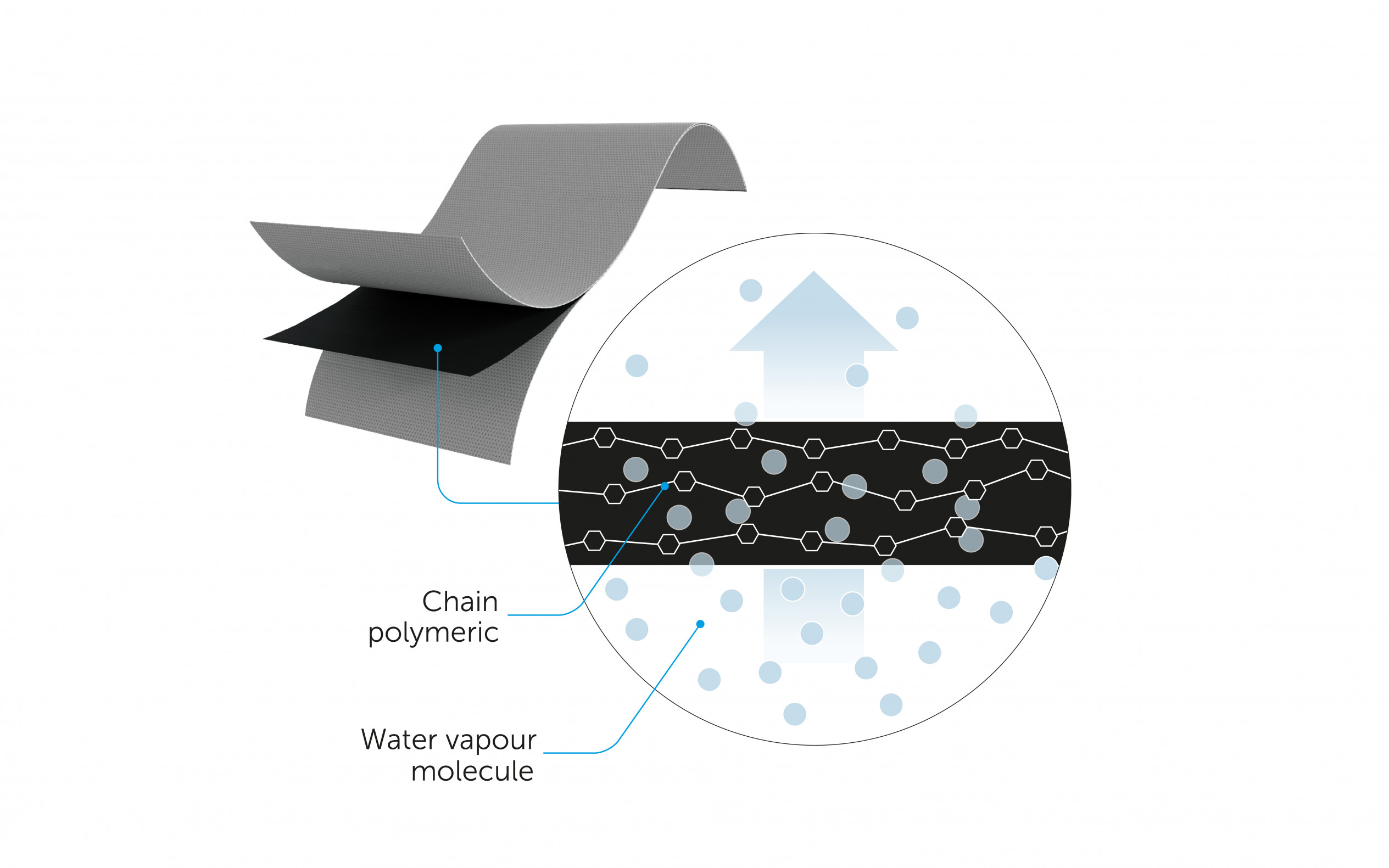

Microporous membranes Microporous membranes are made of hydrophobic polymers, which do not naturally interact with water. These membranes require special processing methods so that water can pass through, and this makes them more susceptible to pollutants.

During production, microporous films are subjected to significant mechanical stress. This process creates micro-holes that allow water vapour to pass through, but, at the same time, make the membrane vulnerable to external contaminants.

Monolithic membranes Conversely, monolithic membranes are composed of hydrophilic polymers that chemically interact with water and are generally more elastic. With this structure, the membranes have better moisture management and greater resistance to pollutants.

Impermeability and breathability

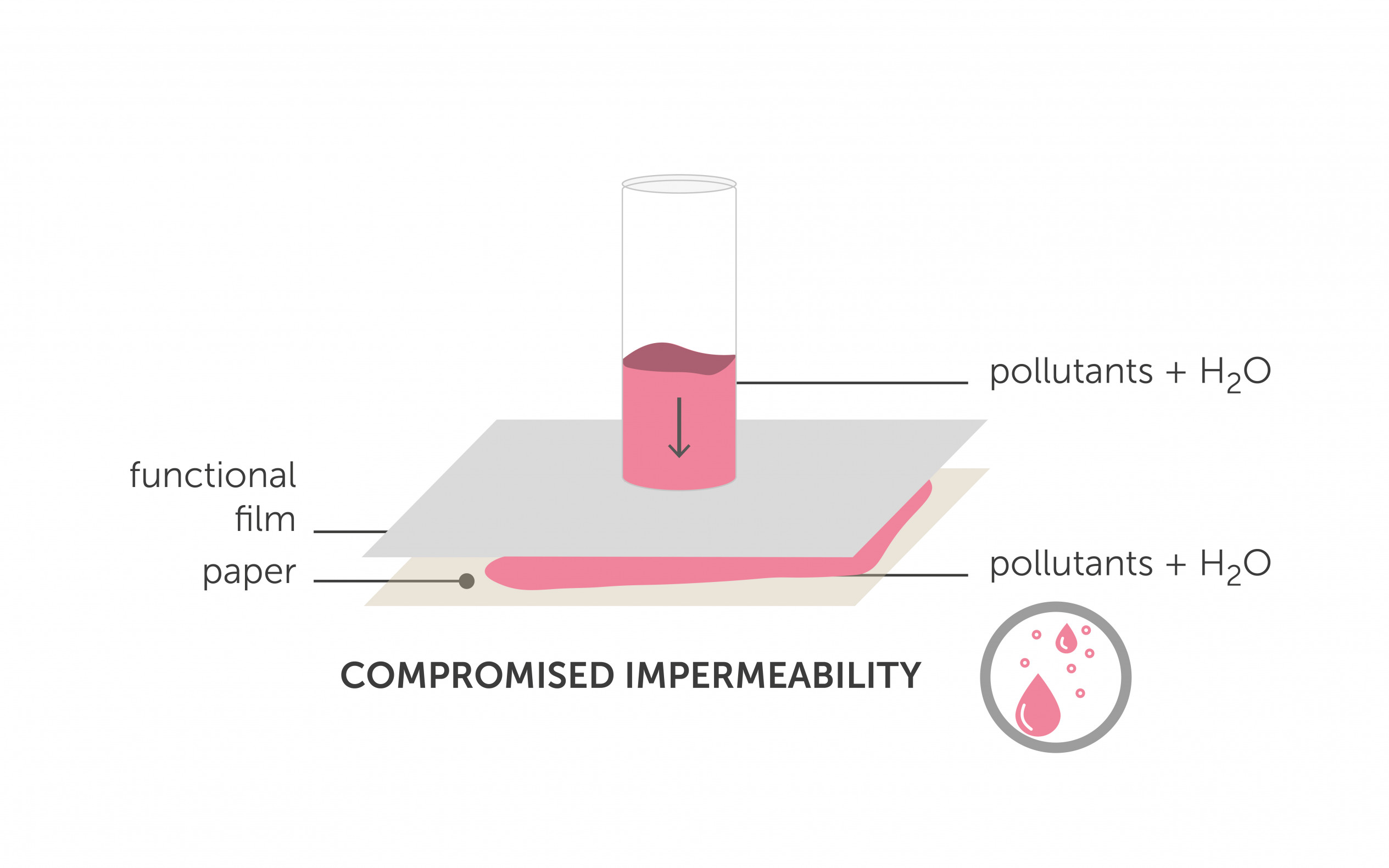

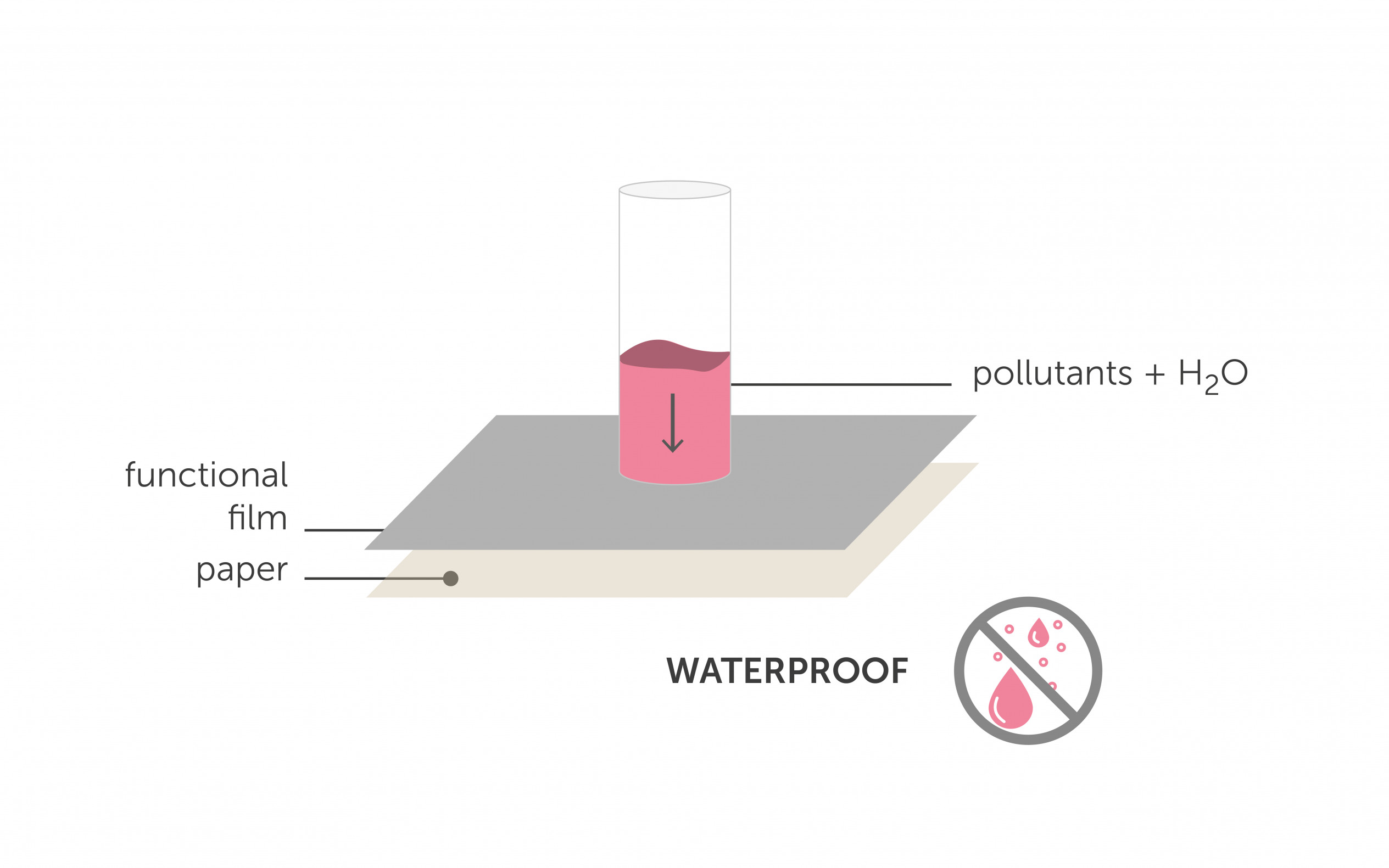

The ability of a membrane to resist water and allow vapour to pass through is crucial to maintaining the integrity of the building. There is a superior balance between impermeability and breathability in monolithic membranes compared to microporous membranes.

Impermeability of microporous membranes. Microporous membranes are designed to be water-repellent by means of surface materials or textures. However, impermeability may be compromised in the presence of pollutants combined with water. When pollutants combine with water, they can break the surface tension and allow the mixture to penetrate through the micro-holes, reducing the effectiveness of the membrane.

Impermeability of monolithic membranes. Because of their chemical structure, monolithic membranes maintain their impermeability even under difficult conditions. Even when pollutants and water are present, monolithic membranes continue to fulfil their protective function without compromise.

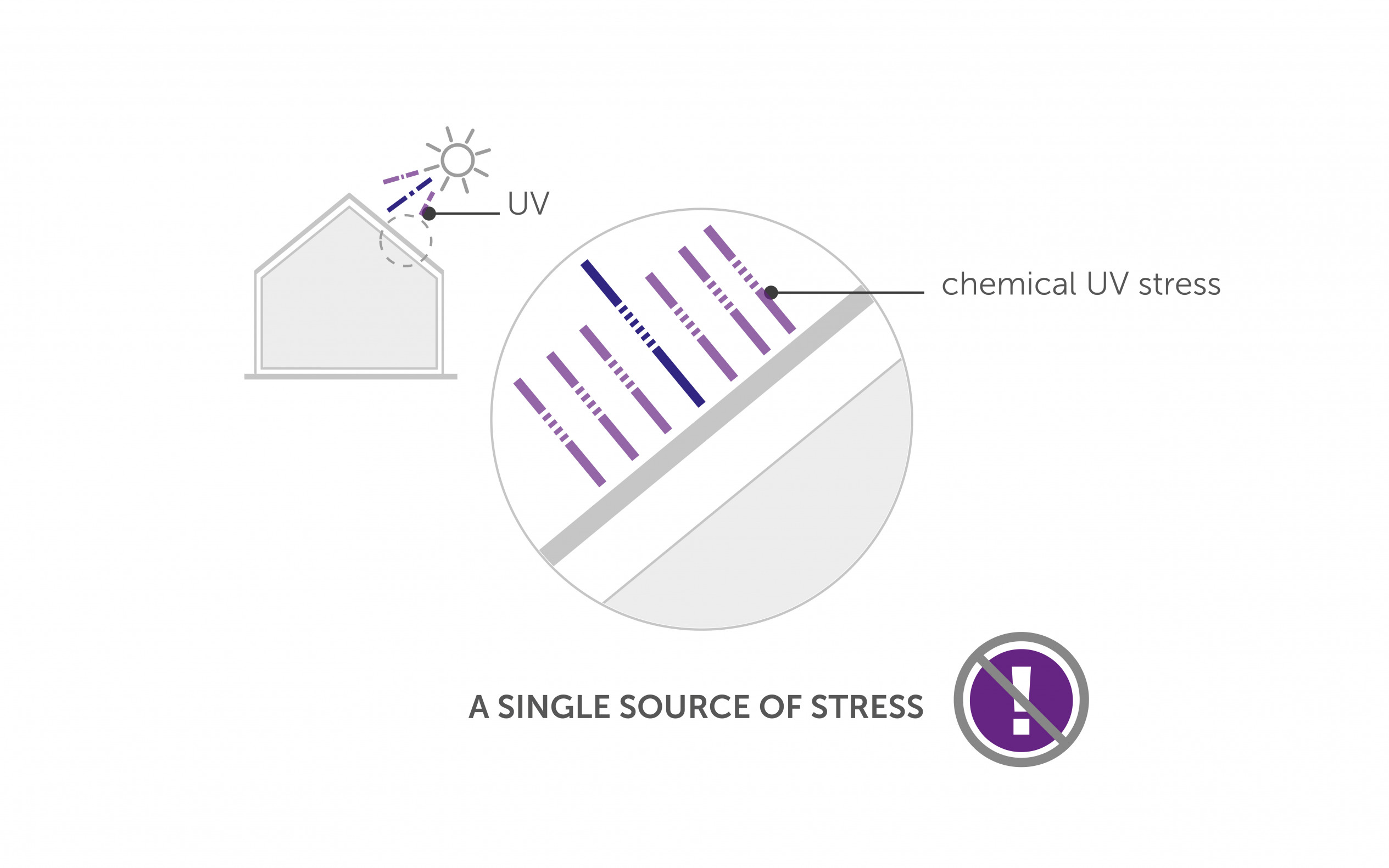

Resistance to Ultraviolet radiation (UV)

The durability of the membranes once exposed to the sun's rays is carefully evaluated through tests to ensure the best results on site. The test method consists of exposing the specimens to continuous UV irradiation at elevated temperature for 336 hours, rising to 5000 hours for products intended for walls with open joints that do not exclude UV exposure.

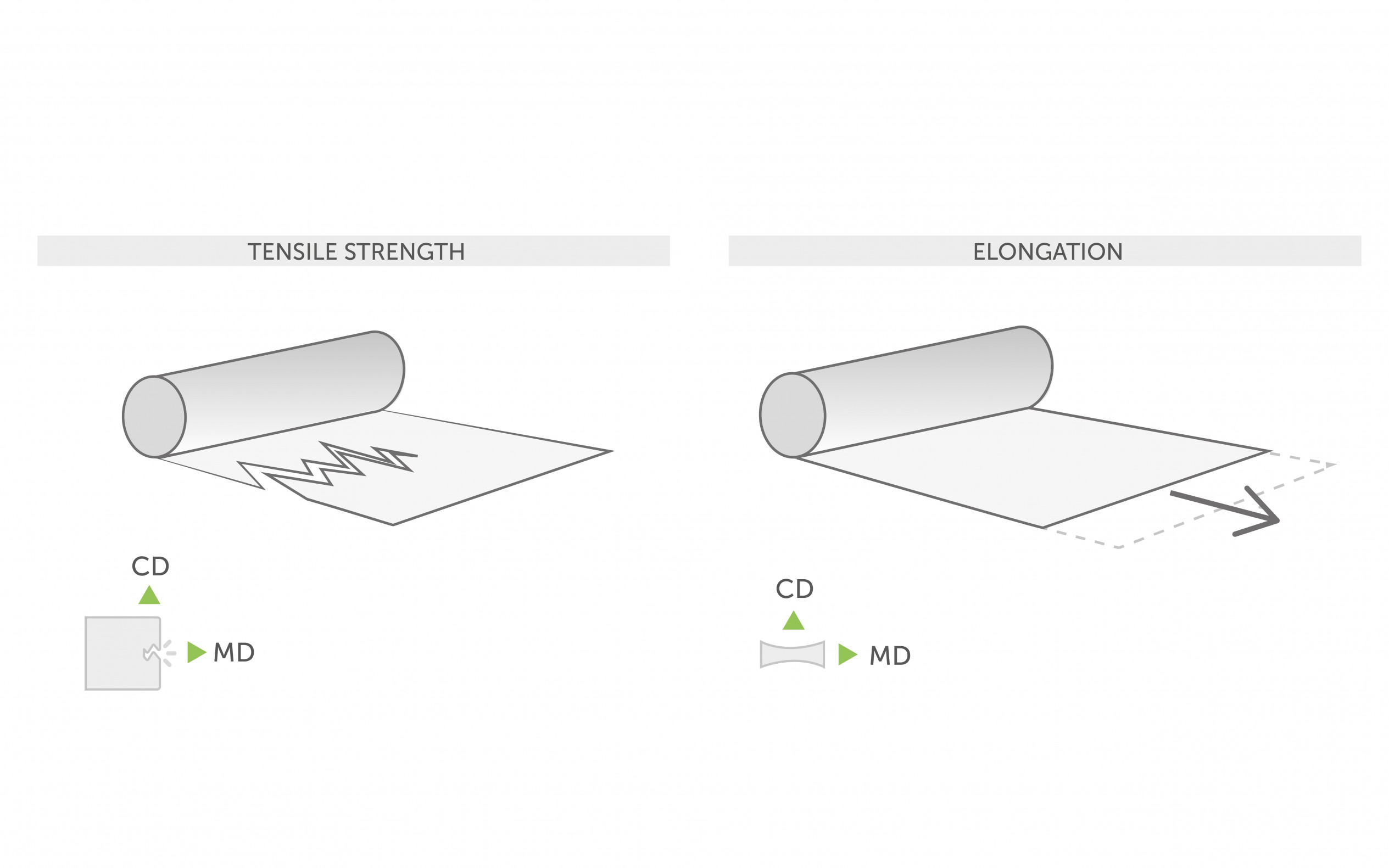

Water penetration resistance, tensile strength and elongation are determined again after artificial ageing to provide performance data even after exposure to these sources of stress.

It must always be borne in mind, however, that actual climatic conditions are variable and depend on the application context, so it is difficult to establish an exact match between artificial ageing tests and actual conditions.

UV rays and microporous membranes. The mechanical stresses of the production phase of microporous membranes, combined with UV exposure, can accelerate material degradation.

Therefore, it is essential to comply with the maximum UV exposure guidelines to ensure the durability of the functional film. When exposed to UV light, microporous membranes are subject to increased degradation.

UV rays and monolithic membranes. For monolithic membranes, on the other hand, there is no source of stress in the production phase that affects UV exposure, which makes their degradation less significant than for microporous membranes.

Here again, it is essential to comply with the maximum UV exposure guidelines to ensure the longevity of the material, but in general monolithic membranes have greater UV resistance and offer greater durability than microporous membranes.

Practical applications and durability

The choice between microporous and monolithic membranes must always be guided by the specific design requirements, as well as environmental and climatic conditions.

While monolithic membranes tend to offer greater durability in variable climatic conditions, microporous membranes may be suitable for less critical situations.

Stress factors and durability. Various tests are carried out on membranes to determine their performance under different conditions, such as tensile strength, elongation and nail tear strength.

It is therefore important to choose certified products that have demonstrated superior properties in response to these tests, even when not strictly required, to ensure lasting results in buildings.

Laboratory tests and cases on site. Laboratory tests provide indications of the strength and durability of membranes, but actual site conditions may vary significantly.

The project evaluation must also necessarily consider:

- seasonal variations

- orientation with respect to cardinal points

- latitude

- altitude

- meteorological variability and unpredictability on an annual basis

In conclusion, which is better, monolithic or microporous membranes?

In making the choice between monolithic and microporous membranes, it is essential to consider not only the technical properties, but also the specific conditions of use.

With their superior resistance to pollutants and UV radiation, monolithic membranes offer a more robust solution for the most demanding applications. In less critical contexts, where pollutant management is not a significant problem, microporous membranes can be used.

Entrust Rothoblaas climate filters for the best and longest lasting protection of your building: they will guide you in choosing the best solutions for your next project.

In the meantime, learn more in the video.

All rights reserved

Technical Details

- Country:

- Any

- Products:

- TRASPIR 110