Introduction to fire safety design and construction details in glulam

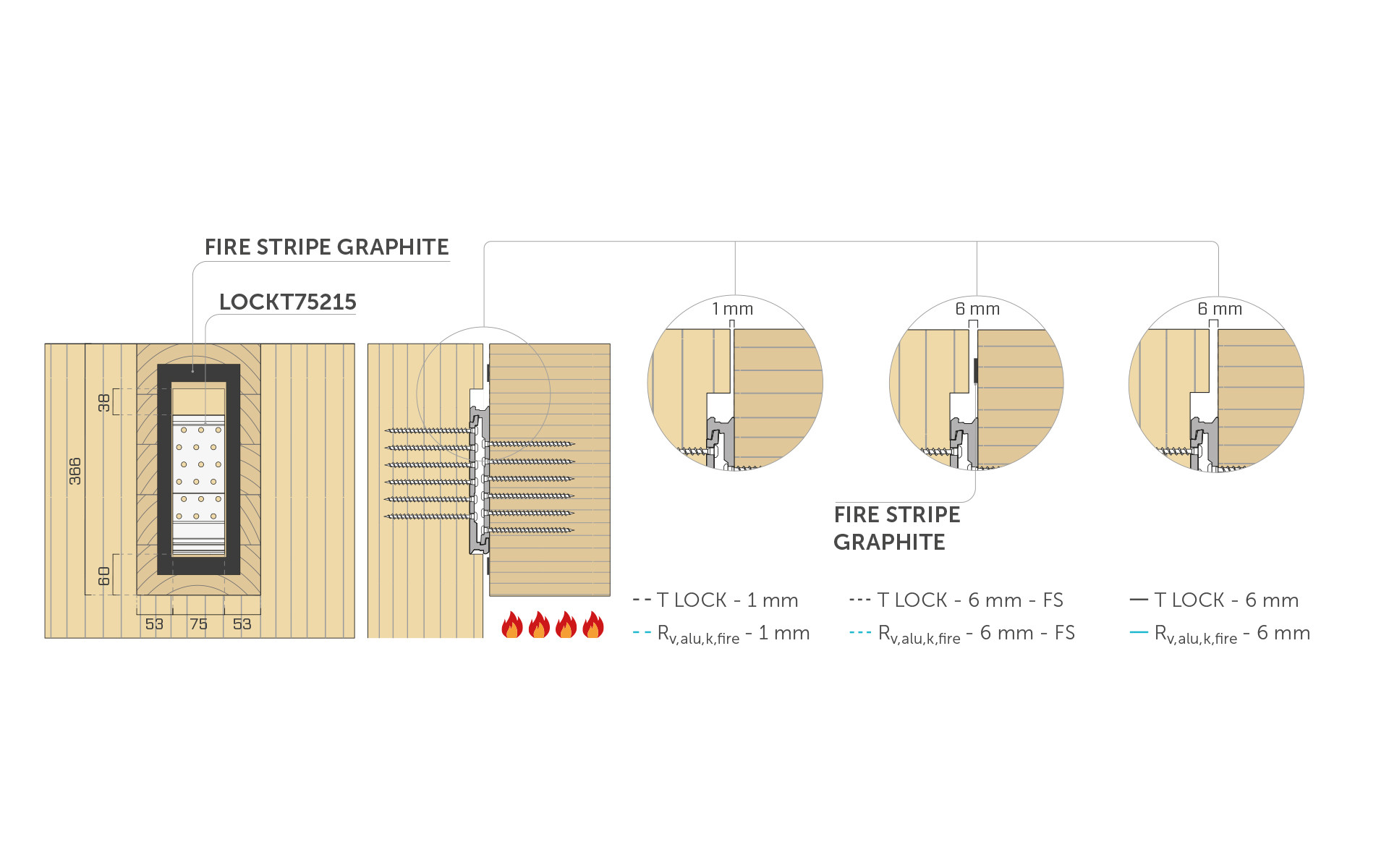

Experimental campaign on LOCK T and installation gaps

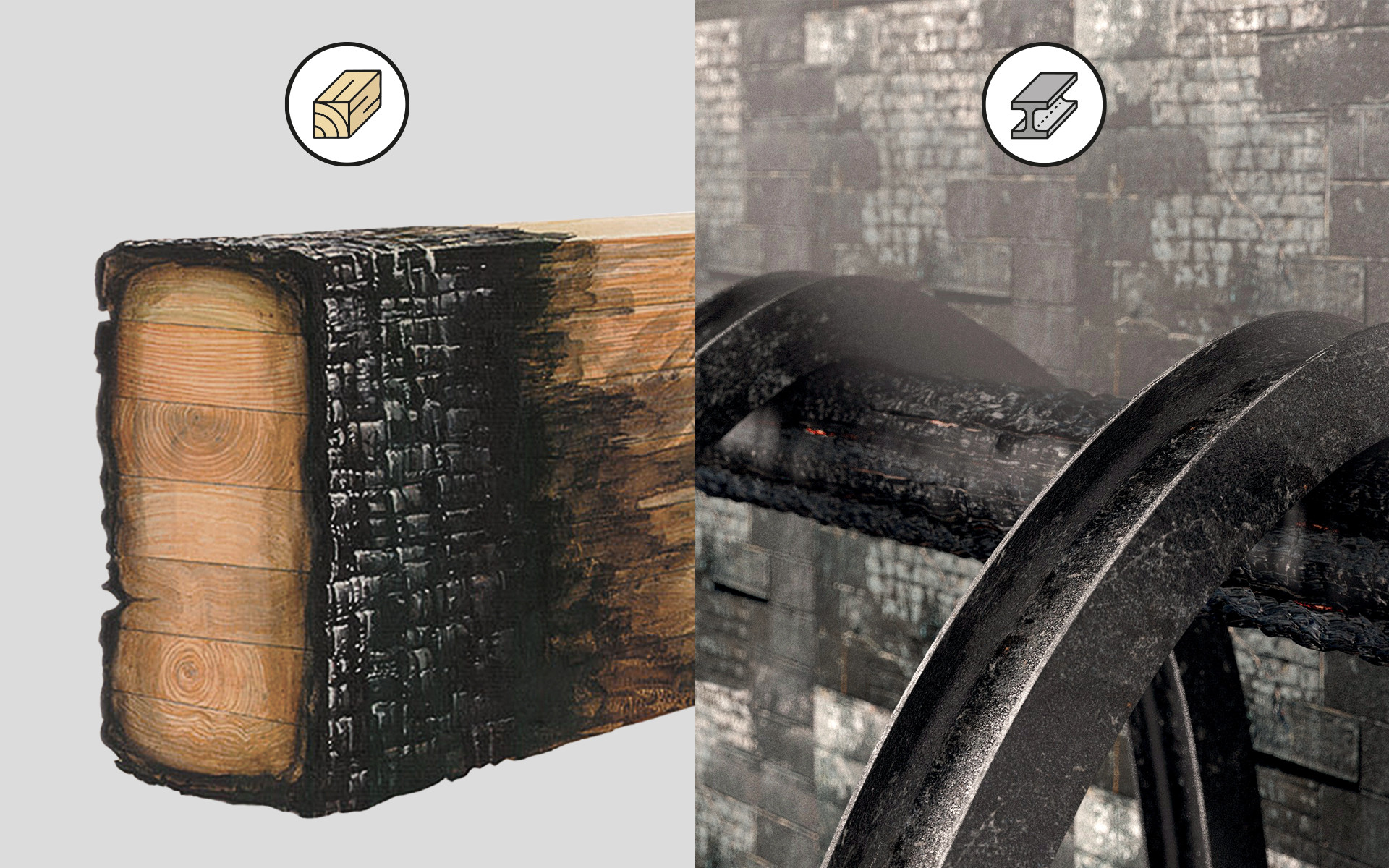

Timber as a construction material carries a long-standing misconception: if wood burns, then how can a wooden building be safe in the event of a fire?

Wood burns, it’s true. But it does so in a more controlled and predictable manner than other materials.

This characteristic, however, does not eliminate the need for meticulous fire safety design, whether for glulam structures, hybrid constructions or those in concrete or other materials.

Special attention must be afforded to construction details involving joints and metal connections, as metals can lose a substantial portion of their load-bearing capacity when subjected to high temperatures.

Aluminium, in particular, exhibits greater thermal sensitivity than steel.

This means that during a fire, the strength and stiffness of aluminium can rapidly deteriorate, potentially compromising the stability of the entire timber structure if the construction details are not properly designed.

In the field of fire safety design, international standards such as EN 1995-1-2 (timber) provide guidelines for assessing fire resistance and the proper application of passive protection and intumescent systems.

However, regulations alone are not enough. Practical solutions and nodes must be tested through experimental campaigns.

That’s why at Rothoblaas, we have conducted extensive testing on this topic, including tests carried out after the original research referenced here, which was conducted by researchers from the Danish Institute of Fire and Security Technology (DBI) and the Technical University of Denmark (DTU) at DBI’s test facilities. One of the most important findings came from the LOCK T 75215 connector, assessed in various gap configurations. The results highlighted the practical implications of designing fire-resistant connections for glulam post-and-beam systems, which must consider not only the connector and the timber, but also a range of additional elements.

Aluminium behaviour and the importance of fire safety design in timber construction.

To optimise fire safety design, it is crucial to understand how aluminium behaves at high temperatures.

Beyond 200–250°C, aluminium’s strength significantly decreases; past 300 °C, its load-bearing capacity is severely compromised.

In contrast, timber tends to char, forming a protective insulating layer on its surface. However, empty spaces (gaps) around the connectors can allow hot air to penetrate deeper, thus increasing the metal’s thermal exposure.

Looking at the cross-section of a timber element after it has been exposed to fire, three layers can be identified:

• a charred zone corresponding to the layer of wood completely affected by the combustion process;

• a heat-affected (pyrolysis) zone that has not yet been charred but has undergone temperature increases above 100°C, which is assumed to have zero residual resistance;

• a residual section that retains its initial strength and stiffness properties.

By positioning the connector within the residual section, the fire performance required by the design can be achieved. However, installation requirements, as well as installation tolerances can lead to a gap between the timber elements. Inside this gap, profiles (FIRE STRIPE GRAPHITE) can be inserted, which, expanding through the heat of the fire, seal the gap and insulate the connector.

The construction details, therefore, must consider:

The positioning and type of metal connectors.

The need to reduce or protect cavities.

The selection of protective systems able to enhance fire resistance.

Experimental campaign on the LOCK T MIDI connector

The testing conducted on LOCK T 75215 included both small-scale (unloaded) and large-scale (loaded) tests to evaluate its behaviour under various standard fire conditions (ISO 834 curve). The tested beam was designed for a fire resistance of 60 minutes, which was the target across all configurations.

The main variables analysed were:

Gap size: 1 mm, 6 mm, 22 mm.

Use of intumescent materials (FIRE STRIPE GRAPHITE) to reduce the inflow of hot air.

Application of a mechanical load in large-scale tests to simulate real operating conditions

Results – unloaded tests

1 mm gap: after 80 minutes of standard fire conditions, the temperature of LOCK T 75215 reached 97±1 °C, indicating relatively limited heating.

6 mm gap: the temperature of the connector rose to approximately 286±36 °C within the same period of time, highlighting how increased spacing allows greater penetration of hot air and a significant rise in temperature.

Use of intumescent material: With a 6 mm gap, the application of FIRE STRIPE GRAPHITE reduced the temperature of the connector from approximately 280°C to 140°C, thus improving fire protection.

Loaded tests

When testing was conducted on near full-scale samples under a mechanical load, LOCK T MIDI exhibited failure at temperatures around 315 °C:

6 mm gap: collapse occurred at 87 minutes (well beyond the 60-minute target).

22 mm gap: collapse occurred much earlier, at 32 minutes, (which is still a reasonable timeframe considering the connection was fully exposed)

These findings confirm that excessive gaps lead to more rapid heating, resulting in premature loss of the aluminium’s load-bearing capacity. Moreover, the load-bearing capacity of connectors significantly decreases as the temperature rises.

After 60 minutes of fire exposure, the estimated reduction in load-bearing capacity is 22% for an unprotected 6 mm gap, 9% for a 6 mm gap with intumescent protection, and 6% for a 1 mm gap, underscoring the importance of fire safety design and construction details that minimise gaps and effectively protect them.

Fire safety design guidelines for joints with metal connections

Minimise gaps

Minimise the space between the aluminium connector and the timber surface as much as possible. The limited flow of air slows down the otherwise rapid heating of the metal, thus extending the element’s resistance under fire conditions.Use intumescent materials

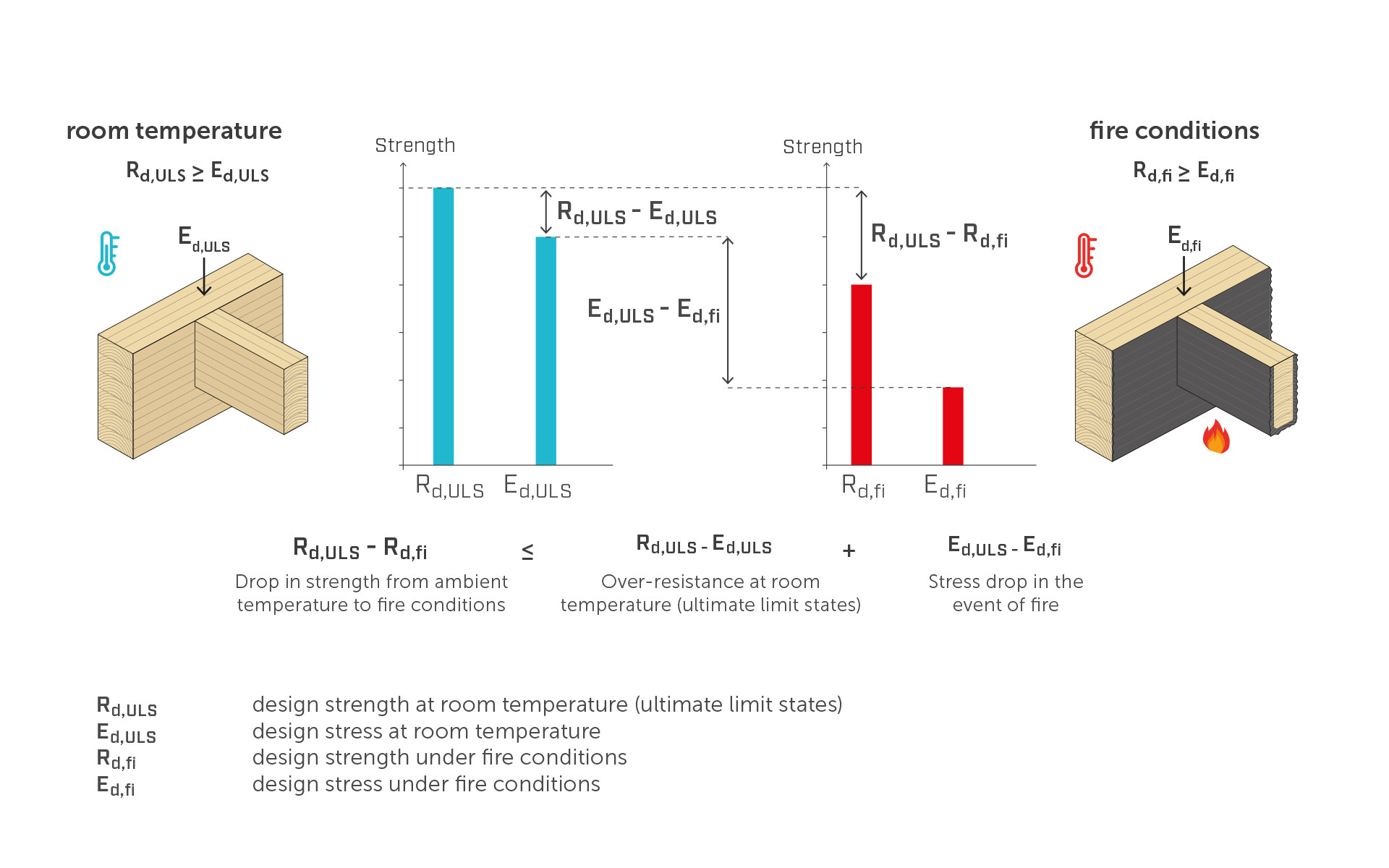

If, due to construction constraints or tolerances, a wider gap is unavoidable, applying FIRE STRIPE GRAPHITE can drastically reduce the maximum temperature reached by the connector.Fire design

In fire safety design calculations, the assessment of a connection begins at ambient temperature, with a focus on the ultimate limit states (ULS). It is good practice to design the connection for a working ratio below unity (e.g. 80%), ensuring that the design strength exceeds the applied load.Incorporate additional passive-intumescent protection

Beyond minimising gaps, the use of gypsum board, calcium silicate or other fire-resistant cladding can slow down flame propagation and reduce connector overheating, optimising the construction details with a view to prevention.Incorporate the relevant regulations into the construction details

Comply with EN 1995-1-2 (structural fire design for timber), taking into account any applicable national regulations, to ensure that structures meet the fire resistance requirements (R30, R60, R90, etc.).

Experimental tests conducted on LOCK T MIDI clearly demonstrate how gap management affects the fire behaviour of aluminium in glulam systems.

A fire safety design approach focused on construction details is key to enhancing safety and structural reliability in the event of a fire.

The ideal choice depends on the specific project requirements, the type of load applied and the required level of resistance to fire. Regardless of the specific conditions, the heating dynamics of the connector and the protective potential of intumescent materials must be assessed from the outset.

Insights and resources

Read the catalogue “CONNECTOR PLATES FOR TIMBER” to find out more.

Request a personalised consultation for support in defining fire safety details.

All rights reserved

Technical Details

- Companies:

- Build in Wood, The Hong Kong Polytechnic University

- Country:

- Any

- Products:

- FIRE STRIPE GRAPHITE LOCK T MIDI