Effect of Tolerances on Timber Fire Performance

Impact of tolerances on the fire behaviour of timber

Concealed connections in timber joints and fire behaviour: experimental results.

LOCK T and FIRE STRIPE GRAPHITE face trial by fire: at CIMAD 2024, the Ibero-Latin American Congress on Wood in Construction, our Spanish team was able to test the influence of gaps and routing on the fire behaviour of joints with concealed metal connections.

The recent study, conducted by the Universitat Politècnica de Catalunya in collaboration with Rothoblaas, EPSEB (Escuela Politecnica superior de edificación de Barcelona) and the Centre de Ciència i Tecnologia Forestal de Catalunya, analysed the effect of even millimetre tolerances on the fire behaviour of joints with concealed connections in timber structures.

The study was led by Laia Haurie, Alina Avellaneda, Ana Lacasta (Universitat Politècnica de Catalunya), Sergio Campesino (Rothoblaas) and Pilar Giraldo (CTFC-INCAFUST).

Comparing timber and concrete: which offers better fire resistance?

Timber and concrete structures generally respond differently to fire. Timber, despite being combustible, develops a charred layer that insulates the core and protects the materials installed within, thereby delaying structural collapse.

Concrete structures, on the other hand, although non-combustible, can experience significant damage and a loss of mechanical strength when exposed to high temperatures.

Comparative studies show that solid timber elements can retain their structural integrity longer than concrete under fire conditions. Timber, for instance, burns at a slow rate of approximately 0.65 mm per minute. Moreover, the surface charring insulates and protects the underlying timber, preserving 85–90% of its structural integrity depending on the size of the element and fire exposure time.

In contrast, concrete can suffer irreversible damage at temperatures above 600 °C and is also at risk of explosive “spalling”, whereby fragments of concrete violently break away due to the internal steam pressure (International Timber) (Cement.org).

What happens to timber joints during a fire: the experimental set-up

The aim of the experiment was to assess how millimetre installation tolerances in connections between timber beams with concealed metal connectors affect the behaviour of joints during a fire.

Three types of connections were tested using GL24h fir glulam:

Connection without tolerance.

Connection with 4 mm tolerance.

Connection with 5 mm tolerance, sealed with FIRE STRIPE GRAPHITE intumescent gasket.

The connector used was LOCK T by Rothoblaas. Each connection was tested with and without routing on the main timber element, which also affects the connector's exposure to the fire.

For each type of connection, two thermocouples were inserted: one in the contact area between the timber beams and another at the connection between the metal plate and the secondary beam. A third thermocouple was used to monitor the temperature of the flame.

Figure 1 shows the three connection configurations before the test (a: without tolerance, b: with 4 mm tolerance, c: with 5 mm tolerance and intumescent gasket).

The experiment then involved applying a direct flame to the joining area between the two beams, and lastly recording the temperatures at the timber-to-timber and timber-to-steel connection points.

Figure 2 shows the fire test moment

Results and possibilities

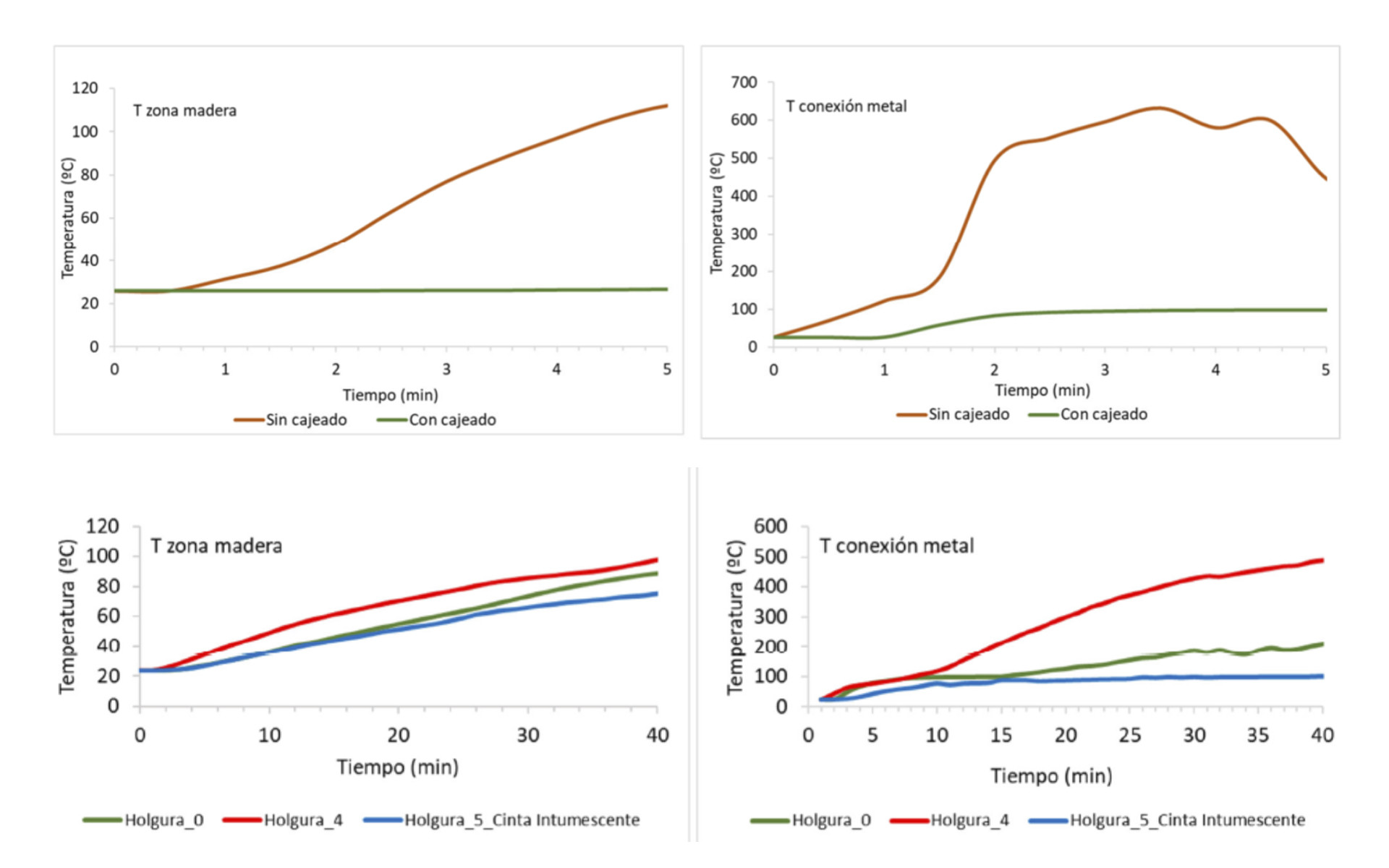

The experiment clearly demonstrated the impact of heat transfer from metal to timber when metal connectors are installed with different tolerances.

In the case of the connection applied to the timber without routing, the temperature in the area between the timber and LOCK T exceeded 500 °C after 2 minutes. The connection inserted in the beam with routing, on the other hand, remained below 100 °C.

The connector with an unprotected tolerance zone showed a rapid increase in temperature, reaching approximately 500 °C after 40 minutes, whereas the connection in the beam with routing and without any tolerance gap reached around 200 °C.

The inclusion of a FIRE STRIPE GRAPHITE intumescent gasket proved effective in blocking the passage of hot gases, maintaining lower temperatures compared to the connection without tolerance.

Figure 4 shows the impact that undercutting can have on temperature evolution at the connection, and the temperature evolution during the test in the different configurations.

In the exposed connection without routing for its insertion in the beam, the temperature in the timber-metal contact area exceeded 500 °C after only 2 minutes, whereas in the joint with a recessed connection, and with a recessed connection plus intumescent gasket, the temperatures remained significantly lower.

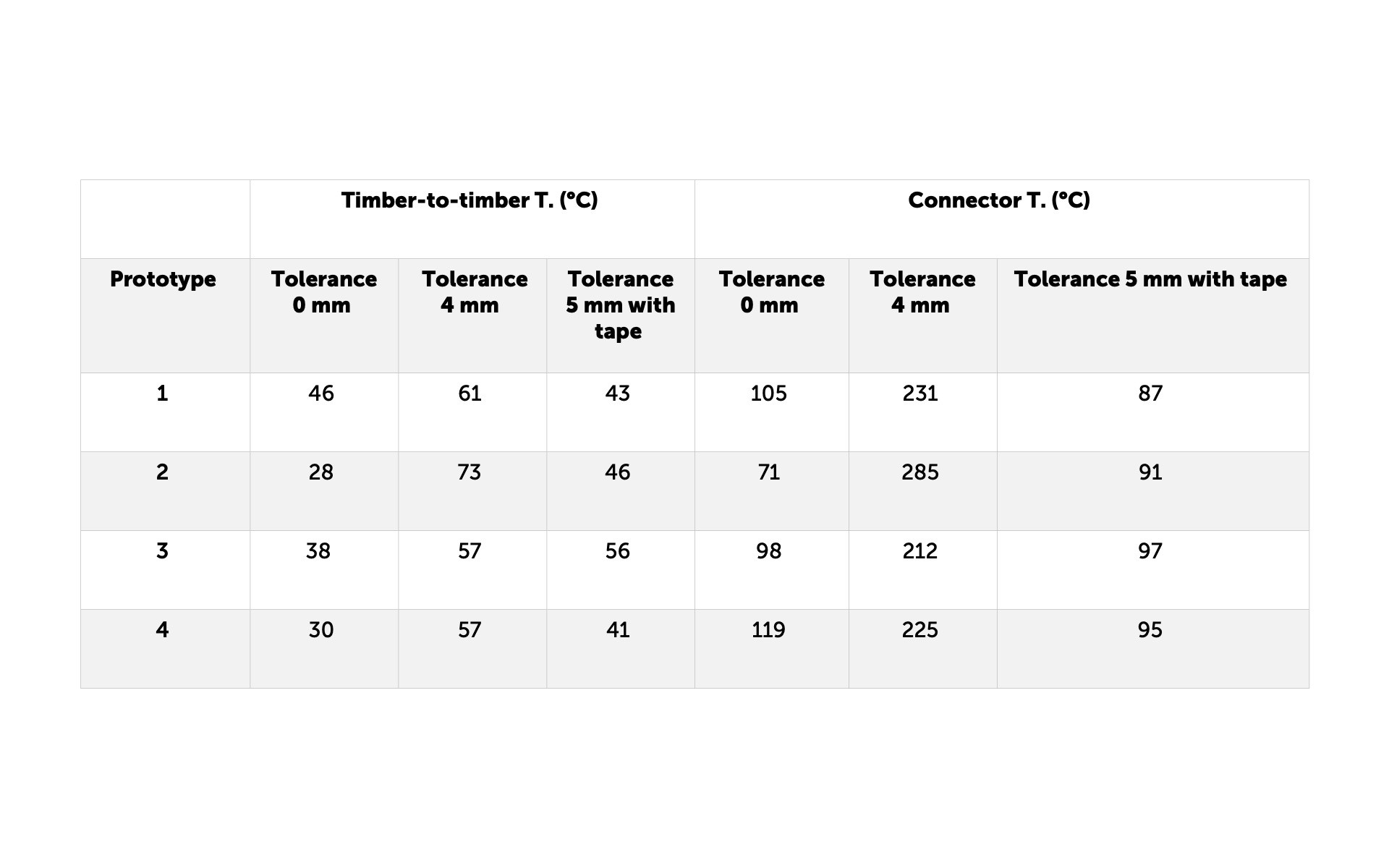

Table 1 summarises the temperatures recorded for each prototype 15 minutes into the experiment.

Conclusions

The study confirmed that protecting concealed metal connections by means of routing is an effective strategy for reducing fire risk.

Connections installed with a tolerance, but not protected, showed increased charring and a reduction in the cross-section of the timber. The use of an intumescent gasket such as FIRE STRIPE GRAPHITE was shown to effectively protect the connector, improving its fire behaviour also with respect to connections applied without a tolerance gap.

Rothoblaas fire resistance products

To maximise fire resistance in timber structures, Rothoblaas offers a range of specialised products, including the FIRE STRIPE GRAPHITE intumescent gasket, specially designed for this purpose.

These solutions are engineered to enhance the fire resistance of concealed metal connections and reduce the risk of structural collapse.

More information is available in the brochure for Rothoblaas fire resistance products.

Fig. 5. Joints after exposure to open flame

All rights reserved

Technical Details

- Companies:

- ROTHOBLAAS

- Country:

- Any

- Products:

- LOCK T FIRE STRIPE GRAPHITE