Timber beam plates and corrosion

In hybrid and CLT constructions, timber beam connectors are crucial in ensuring both stability and design flexibility. However, their susceptibility to certain external factors is often underestimated as compared to the primary material: timber. Screws, timber beam plates and other metal elements are not merely functional accessories; they are critical components that, if neglected, can jeopardise the longevity of the entire structure.

In certain conditions, timber beam connectors can be particularly vulnerable to external factors such as humidity, weathering and chemical reactions between the substances in the timber and the metal plates.

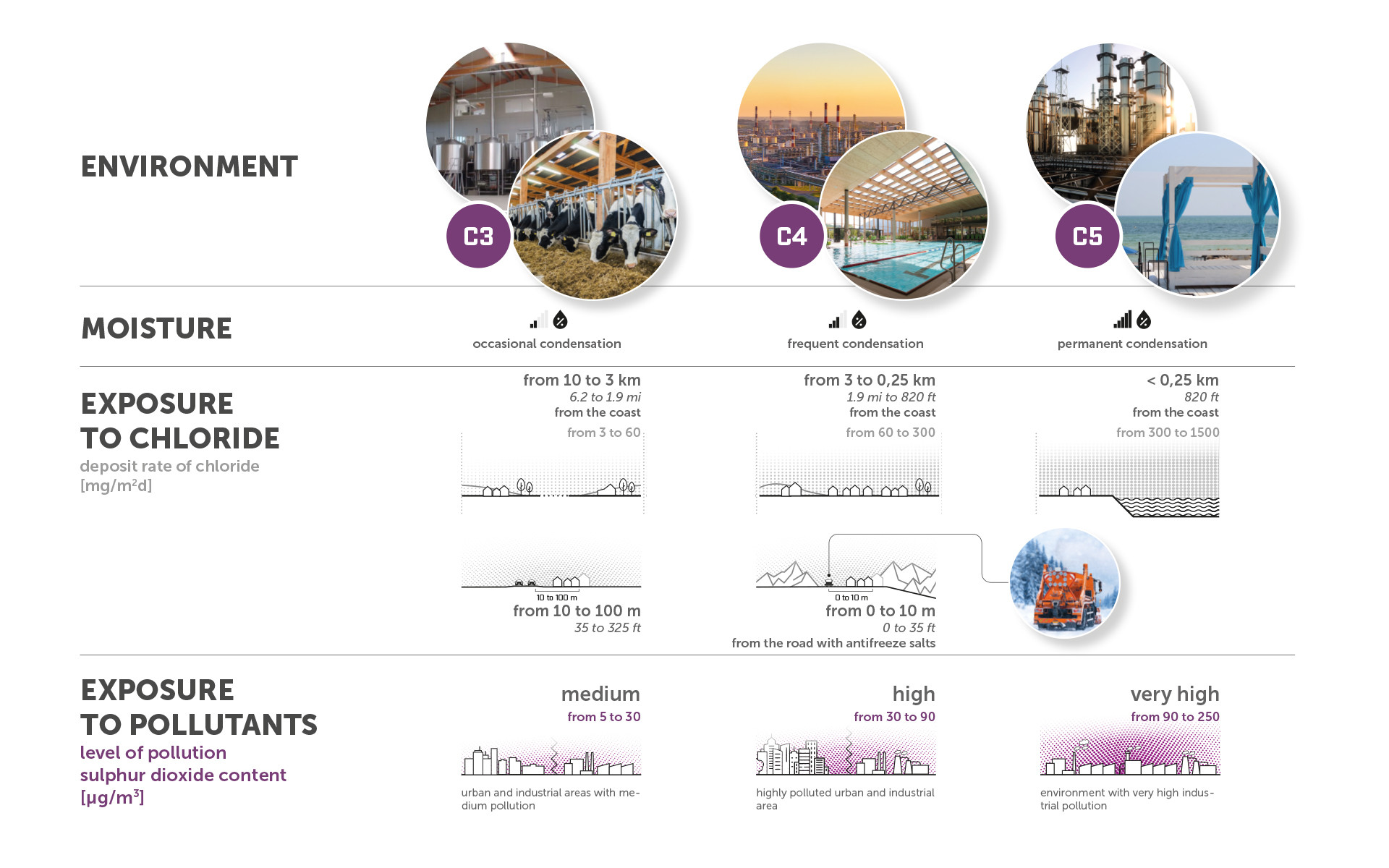

These factors become especially critical in outdoor settings or harsh conditions, such as coastal or industrial areas, where the metal components of timber beam plates are more prone to rapid corrosion.

Designing with durability in mind equates to minimising maintenance requirements and extending the life of the entire structure. However, factoring in this aspect often introduces complexities that most designers prefer to overlook.

The solution lies in simplifying the process of evaluating risk factors and determining corresponding measures.

When regulations fall short: limitations of Eurocode 5

Structural requirements outlined in standards such as Eurocode 5 (EN 1995-1-1) provide a solid foundation for timber design, introducing the concept of Service Class (SC) to evaluate material performance under varying environmental conditions. However, these standards often address durability primarily from the perspective of the timber itself, affording little attention to the durability of the connections.

The service classes defined in Eurocode 5 (prEN1995-1-1 - Final Draft 22.01.2021) range from SC1 (dry indoor environments) to SC4 (continuous immersion), addressing the issue based on thermo-hygrometric parameters. However, they overlook critical aspects such as:

Atmospheric corrosivity: agents like chlorides or pollutants can rapidly degrade metals.

Timber-metal interaction: certain types of timber, especially treated or highly acidic varieties, accelerate the deterioration of timber beam connectors.

Galvanic coupling: electrochemical corrosion, caused by contact between different metals, is a potential failure factor for timber beam plates.

This approach can lead to incomplete design choices, particularly for structures exposed to complex environmental conditions.

Consider, for example, a structure located in a coastal area with high chloride levels – the connections will likely have a significantly shorter lifespan if corrosion-resistant materials are not considered when selecting the timber beam connectors.

The three key parameters for corrosion-resistant design.

To ensure the durability of connections using timber beam plates, it is essential to consider three primary variables:

Service Class (SC) according to prEN1995-1-1: defines how timber responds to environmental humidity, influencing the choice of connections.

Atmospheric Corrosivity Class (C) according to EN ISO 9223: measures the aggressiveness of the surrounding environment, ranging from C1 (dry and clean environments) to C5 (highly corrosive environments, such as coastal or industrial areas).

Wood Corrosivity Class (T) according to EN 14592:2022: evaluates the corrosive potential of the timber itself, from T1 (neutral timber) to T5 (timber with high acidity or chemical treatments).

Combining these parameters generates more than 100 theoretical situations – a complex scenario that risks discouraging designers from thoroughly evaluating the corrosion resistance of timber beam connectors.

However, a proper analysis can simplify the selection of the most appropriate connections.

The Rothoblaas durability matrix: a simple solution for complex scenarios

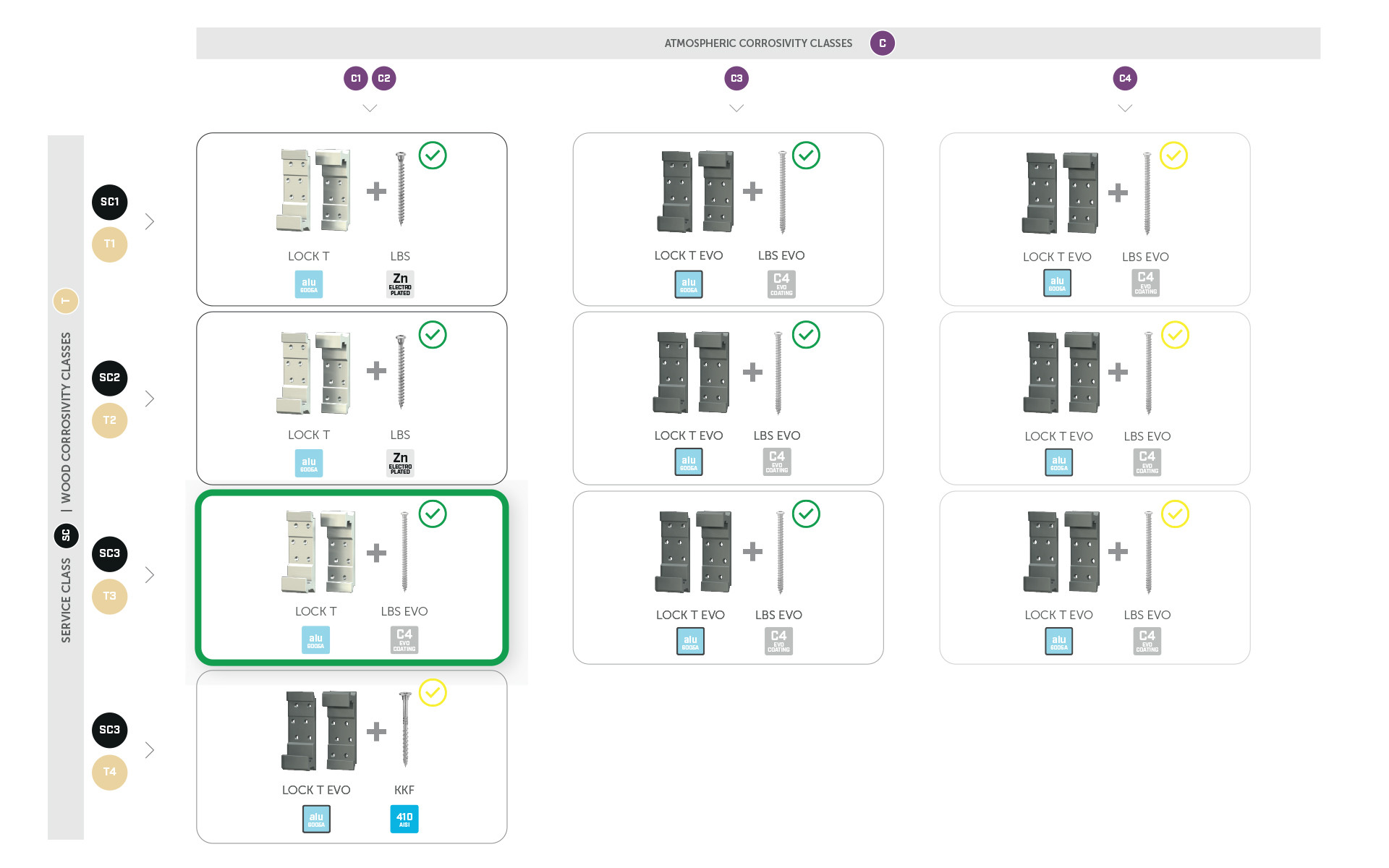

To address this complexity, Rothoblaas has compiled the document “LOCK: connector selection and guide to durability” – a dedicated matrix for timber beam plate connections that:

Reduces the theoretical combinations from 100 to 10 practical scenarios, eliminating any irrelevant conditions.

Guides designers in selecting the most suitable screw-connector system based on the specific project conditions.

The matrix was developed through a detailed analysis of regulations combined with over 30 years of expertise in the timber beam connector industry. This tool significantly simplifies the process, helping designers avoid errors and confidently choose the most appropriate materials.

Rothoblaas solutions: LOCK T MINI and LOCK T MIDI

Among the solutions offered by Rothoblaas, LOCK T MINI and LOCK T MIDI connectors stand out for their ability to effectively address the issue of durability:

They are available in two main versions:

Bare aluminium: suitable for indoor applications or non-critical conditions.

Powder-coated aluminium: ideal for environments with high atmospheric corrosivity.

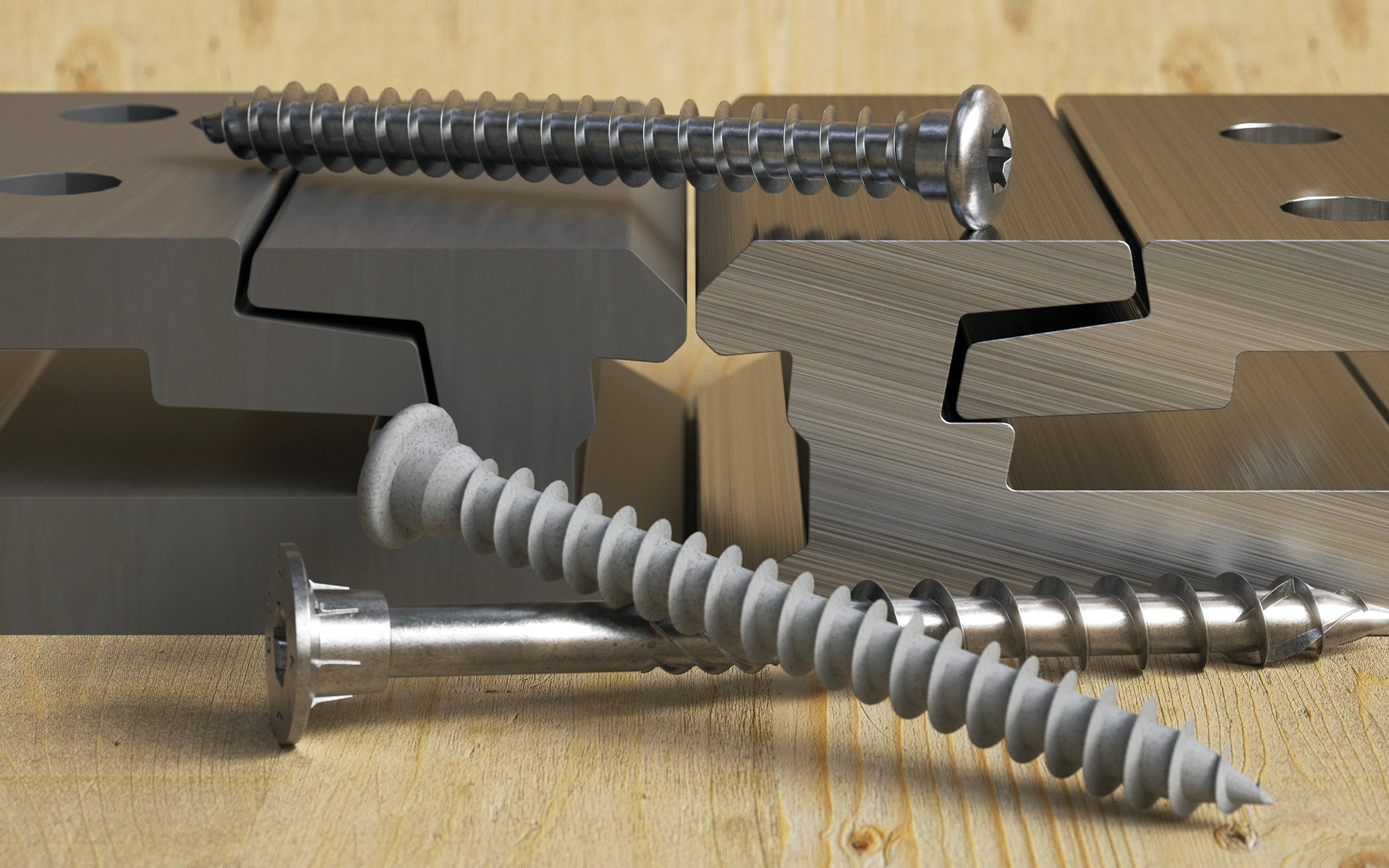

They are compatible with a range of screws optimised for various needs:

Bright zinc plated carbon steel screws: a cost-effective solution for moderate conditions.

C4 EVO coated screws: designed to withstand highly corrosive environments.

Martensitic stainless-steel screws (AISI410): suitable for acidic timbers (class T4) in moderately aggressive environments.

Each version of the connector can be paired with any of these screw types. Thanks to these combinations, LOCK connectors offer a versatile and reliable solution for every type of project.

Applying the Connector selection and guide to durability matrix: A practical example

Let’s imagine designing a canopy exposed to the elements with the following parameters:

Service Class SC3: a structure exposed to rain but without water stagnation.

Wood Corrosivity Class T3: standard, untreated timber (such as spruce).

Atmospheric Corrosivity Class C2: a rural environment, far from the sea, with low pollution levels.

In this case, the matrix suggests the following configuration for timber beam connectors:

Connector: LOCK T in the standard version.

Screw: with C4 EVO coating, ensuring strength and durability for the entire connection and timber beam plates

Designing durable connections requires looking beyond regulatory guidelines and carefully evaluating the operating conditions. With its durability matrix and LOCK T connectors, Rothoblaas provides clear guidance and reliable tools to simplify decision-making and ensure robust, safe structures that stand the test of time.

All rights reserved

Technical Details

- Companies:

- any

- Country:

- Italy

- Products:

- LOCK T MINI LOCK T MIDI