Connections in hybrid construction sites: timber-to-timber, timber-to-steel, timber-to-concrete screws.

Hybrid construction sites represent the smart evolution of modern building, where different structural materials – such as timber, steel and concrete – work in synergy, each leveraging its own unique strengths.

Imagine an orchestra where every instrument contributes its own unique sound: similarly, in a hybrid structure, each material brings its own specific mechanical properties to develop an optimised construction system.

The key to success lies in the strategic distribution of materials. Take a multi-storey building, for example: reinforced concrete columns on the ground floor provide stability and strength for high vertical loads. From the first floor upwards, a load-bearing structure in glulam offers a lightweight solution and excellent seismic performance, with steel beams used to strategically cover wide spans or create large architectural overhangs. Floor slabs can be developed using a composite timber and concrete system, where the concrete structural topping improves stiffness, while the underlying timber framework helps to minimise the overall load.

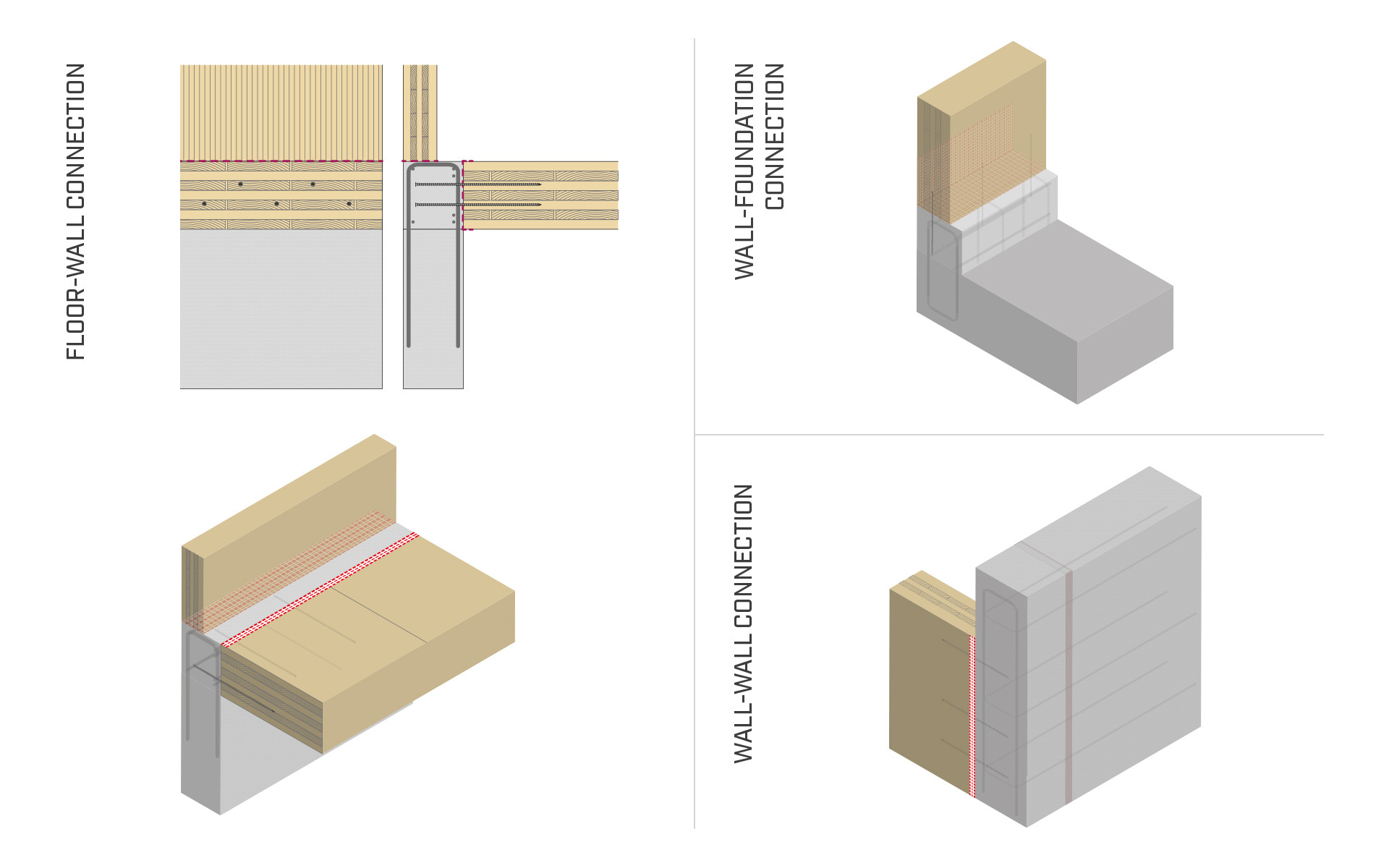

The real engineering challenge lies in managing the interfaces between different materials. These critical joints require meticulous design in order to successfully manage the transfer of forces between elements with vastly different stiffness levels (for example, between timber and concrete).

The design of these construction details requires a thorough understanding of how the materials, and above all the connections, behave.

Through an in-depth study of interfaces, Rothoblaas has developed a range of timber screws, timber and concrete screws, and timber and steel screws ensuring the hybrid structure functions as a single system, optimising each material’s performance and guaranteeing long-term durability.

Timber screws, even timber-to-timber connections, can be hybrid when hard and soft woods meet.

When connecting a hardwood such as oak or beech to a softwood like fir, special timber screws are needed to handle differences in density that can be up to three times greater between materials.

The HARDWOOD series screws (LBS HARDWOOD, HBS HARDWOOD, and VGZ HARDWOOD) represent a significant advancement in this field.

These timber screws have been completely redesigned in every aspect – from head shape to core diameter, thread pitch to tip configuration – to optimise their pull-through into high-density woods.

The result is “concrete”: they create strong, effective connections without pre-drilled holes, even in timbers with a density exceeding 500 kg/m³, thus streamlining on-site operations.

Yet another distinctive feature of these screws for highly dense timber is their technical documentation. The technical data sheets provide certified (ETA) withdrawal strength values for specific hardwood species such as oak and beech, and also for engineered hardwoods, including beech laminated veneer lumber – known as BauBuche in German-speaking regions and BeechLVL in the Anglo-Saxon world – and Plywood; a level of detail rarely available on the market.

This allows designers to optimise connections with engineering-level precision, adapting dimensions to match the specific characteristics of each wood type.

Beyond the technical advantages, this approach also benefits the environment. Enabling efficient use of local wood types reduces reliance on “global timber” (mainly pine and fir) and opens up new possibilities for short, sustainable supply chains. Using locally sourced timber reduces the environmental impact of transportation while making efficient use of local forest resources, contributing to more rational management of woodland heritage.

Timber and steel: choosing the right screw

When timber and steel meet, different scenarios can arise. Designers looking for the right screw for a timber-to-metal connection between hardwood and steel, for example, can once again rely on the range of HARDWOOD timber screws. Designed for connections with metal elements, such as perforated plates – including high-tech solutions such as RING and RADIAL – the HARDWOOD series is equally suited to more common applications, such as light and heavy steel framing structures.

When working with custom-made steel plates designed for medium- and large-scale construction sites – which may, therefore, be of greater thickness – the new version of HBS PLATE offers a sturdier, stronger and more rigid solution.

The challenge of drilling metal: screws and self-drilling dowels

When it comes to timber-metal-timber connections, the SBD dowel stands out as the go-to solution for best results. This technically advanced fastening system, featuring a new tapered tip, outperforms traditional alternatives on the market, delivering superior structural performance while reducing installation times to one-third compared to previous solutions and conventional systems with pre-drilled holes.

While adhesive resin solutions such as XEPOX are highly effective, they require hardening times and strict temperature monitoring during application. By contrast, the SBD system offers major operational advantages. The possibility for dry installation facilitates reassembly and standardised processes, making it particularly beneficial for connections between steel columns and timber beams, where rapid insertion significantly reduces assembly times.

Still on the topic of metal-to-timber connections, HUS – the turned washer by Rothoblaas – ensures perfect compatibility with countersunk head screws in metal plates with cylindrical holes (thus eliminating the need for costly countersinking) while also increasing axial strength in timber-to-timber connections. The HUS 15° version is particularly useful for installations where achieving the perfect screw inclination would otherwise require frustrating, time-consuming adjustments.

A perfect middle ground between its high-performance big sister VGU 45° and the standard HUS, it offers a practical solution for inserting screws in “hard-to-reach” places. For example, tight corners where using a drill can be challenging, ensuring precise installation even in difficult conditions. Or in connections between CLT floor slabs and intermediate-sized steel profiles (IPE or HE) that don't allow pre-drilling with extension, nor access with a drill. The 15-degree angle of the HUS 15 provides an effective and practical solution in these scenarios. For added stability, the system can be further reinforced with a ring-shaped adhesive applied around the washer, ensuring reliable installation even in tricky situations.

Timber-to-concrete connections: composite floor slabs and beyond

In composite timber-concrete floor slabs, where timber and concrete must be joined, the CTC connector is an optimised technical solution for medium-scale projects and structural rehabilitation.

CTC stands out for its versatile application across all types of timber, including solid and engineered timber, in addition to its ease of use: a dry-installation system that requires no resins or additional rods – instead, screws are inserted in sequence to create a strong, effective connection between the concrete slab and the underlying timber framework.

The technical certification (ETA-19/0244) for CTC includes performance values calculated for various types of timber and concrete floor slabs, from solid timber to CLT, and from standard C20/25 concrete to lightweight mixes, offering a wide range of construction possibilities.

The system also allows for the integration of soundproofing layers, such as SILENT FLOOR for acoustic insulation, while the module dedicated to composite timber-concrete floor slabs on MYproject simplifies the calculation of connections between timber and concrete elements.

The TC FUSION innovation represents the next technological advancement in timber-to-concrete connections with high structural performance.

Developed to create moment-resisting joints in timber floor slabs, this system draws inspiration from reinforced concrete construction principles, adapting them to timber structural engineering. The goal? To ensure effective stress transfer between timber and concrete.

The result is a highly effective solution for post-and-beam construction systems, enabling the restoration of bending strength in floor slabs.

With extensive certification of screw withdrawal strength values, this product provides designers with greater flexibility in the design of timber and concrete floor slabs, backed by a standardised application model, specifically tested for timber-to-concrete interfaces.

This system is particularly suited to both connections reliant on the axial strength of screws, such as hold-down joints, and wall-to-wall and floor-to-wall connections.

These technical solutions effectively meet the various requirements of timber-to-concrete fastening, providing a reliable alternative for developing joints between composite elements, both in new builds and in structural rehabilitation projects.

The future of screws is hybrid.

From systems for timber-to-timber connections with HARDWOOD technology, to solutions for metal-to-timber interfaces like SBD and HUS, as well as CTC and TC FUSION connectors for timber-concrete floor slabs, every solution has been developed to enhance both performance and ease of installation in hybrid joints. Timber screws are undoubtedly the present, but the future lies in the complete range of solutions allowing designers to explore new building possibilities, ensuring maximum reliability thanks to certified, tested strength values.

To find out more about the possibilities offered by these connectors, visit the timber screws section of the Rothoblaas website: https://www.rothoblaas.com/products/fastening/screws

All rights reserved

Technical Details

- Companies:

- any

- Country:

- Any

- Products:

- LBS HARDWOOD TC FUSION SBD HUS HBS HARDWOOD VGZ HARDWOOD RING RADIAL HBS PLATE VGU XEPOX D - DENSE XEPOX F - FLUID XEPOX G - GEL XEPOX L - LIQUID XEPOX P - PRIMER SILENT FLOOR PUR