BMU vs. H-RAIL

Applications, comparisons, advantages of horizontal track

Often large buildings have large windows and limited manoeuvring space for façade maintenance. When it comes to window cleaning, for example, there are few alternatives that guarantee the execution of work and the safety of operators. Among these, the most common are BMUs (Building Maintenance Units) and systems that integrate horizontal rails for rope access.

BMUs, also referred to as "baskets," are lowered from the roof and move along the wall carrying 1 to 6 operators at most. The aesthetic impact of BMUs on a building is very significant: mechanical booms on the roofs and large footprint of the machines in their resting position.

In contrast, systems that integrate horizontal rails for rope access, such as Rothoblaas' new H-RAIL, are an unobtrusive, elegant, and quickly assembled solution.

In addition to its ability to be used in fall arrest and restraint, H-RAIL has many advantages over a BMU.

When applied in suspension, a comparison of the two solutions points out these features.

Footprint and weight

BMU: BMUs installation requires space to accommodate a large machine. On the rooftops of some very tall buildings, mechanical booms requiring permanent space are installed. The building design must consider the weight load, which is often significant, of the BMU system.

H-RAIL: once installed, the rail requires no additional space. In fact, the footprint of H-RAIL is extremely small. The standard product is easy to find and fits into the building design without major problems.

Aesthetics

BMU: the baskets are aesthetically very impactful even when not in use. For installation, they require fixed or mobile devices.

H-RAIL: small in size and easily concealed within the architectural structure, it is often invisible. Made of aluminium, on request also available anodised or painted in various RAL colours.

Ergonomics and operator safety

BMU: during work, operators have to lean out to reach the front and the basket often swings.

H-RAIL: the rail allows suspended work, the operator is slinging and remains at the correct distance from the wall.

Speed

BMU: depending on the size of the basket, 6 operators are allowed to work at the same time. On large surfaces, façade maintenance times are very long.

H-RAIL: 4 operators are allowed to work on a rail at the same time and over a larger area than a basket. The speed of execution of the works is greater.

Adaptable

BMU: curved buildings, sloping façades, angles and narrow spaces are difficult to reach.

H-RAIL: even in the case of constructions with complex shapes, the rail allows freedom of movement and execution of maintenance or cleaning work.

Costs and time

BMU: both very high for installation and maintenance of crane and basket motors.

H-RAIL: rope access is a great "cost and time saver" as the system is quick and easy to install and maintain compared to BMUs.

The features of H-RAIL: safety, speed, versatility

Horizontal rigid anchor lines with few fixings, curved or straight rigid lines: thanks to the versatility and modularity of the H-RAIL rail system from Rothoblass, work in fall protection, restraint and suspension is extremely safe. Installation is quick, with fewer installation constraints than competitive products. H-RAIL is a system that can be used in numerous contexts.

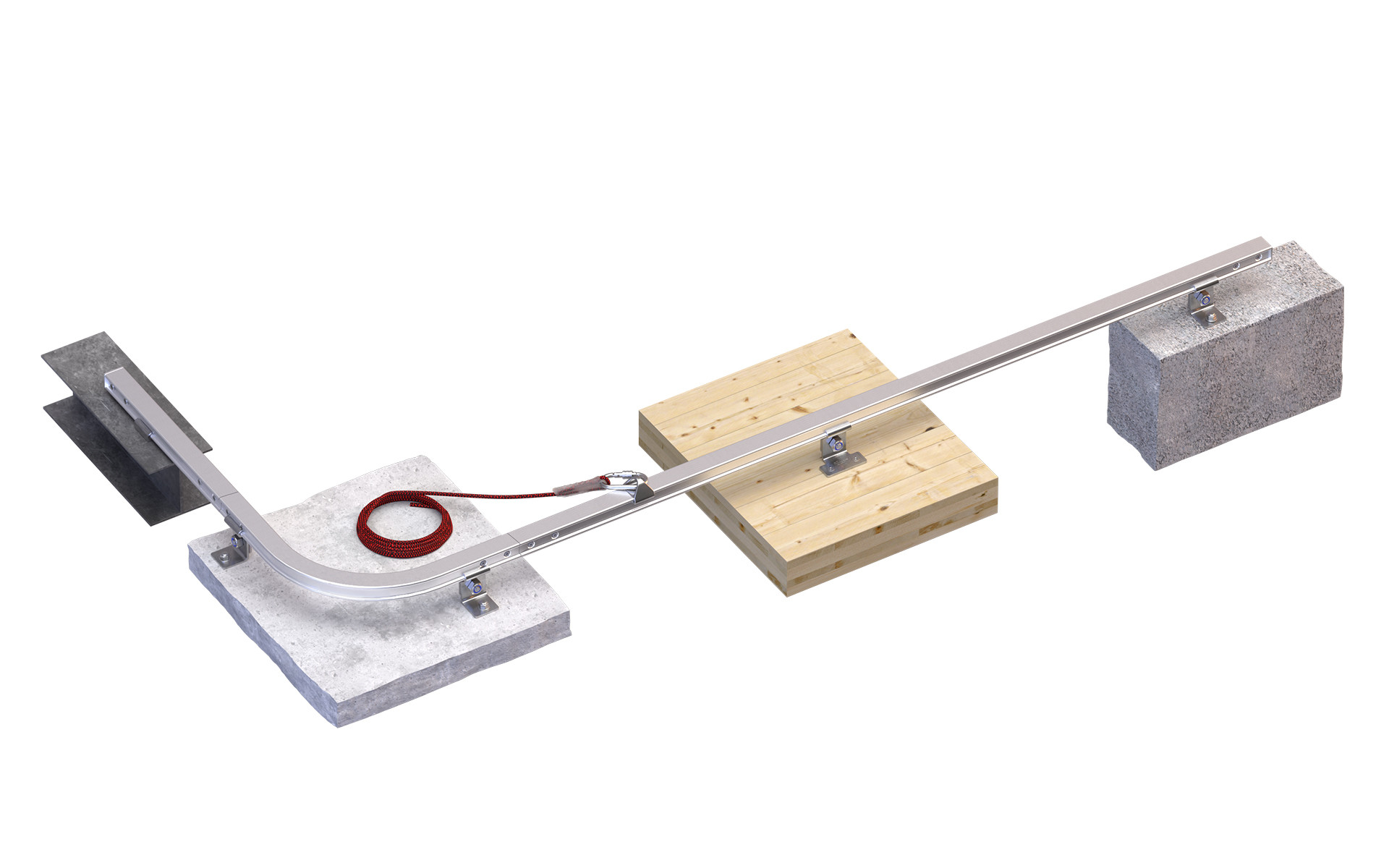

H-RAIL ON FLOOR, rail system for horizontal use

Assembly of this floor version requires a limited number of fastening points with support spacing up to 6 metres.

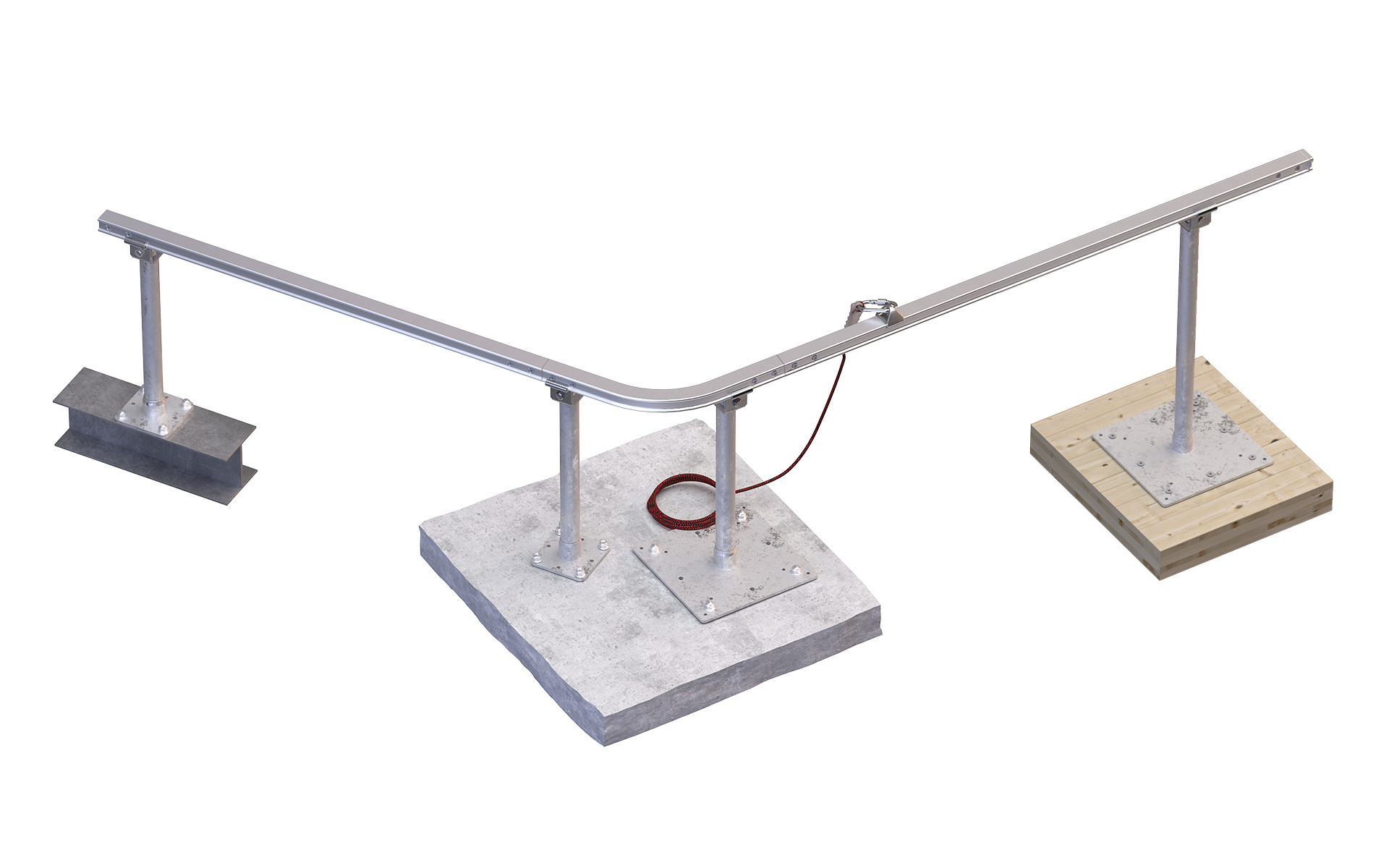

H-RAIL + TOWER / TOWER A2 / TOWER XL, rail system for horizontal use on supports

Modular, it can be assembled in combination with TOWER, TOWER A2 and TOWER XL by Rothoblaas. The combination of the supports allows the rail to be raised and any obstacles in the roof to be overcome.

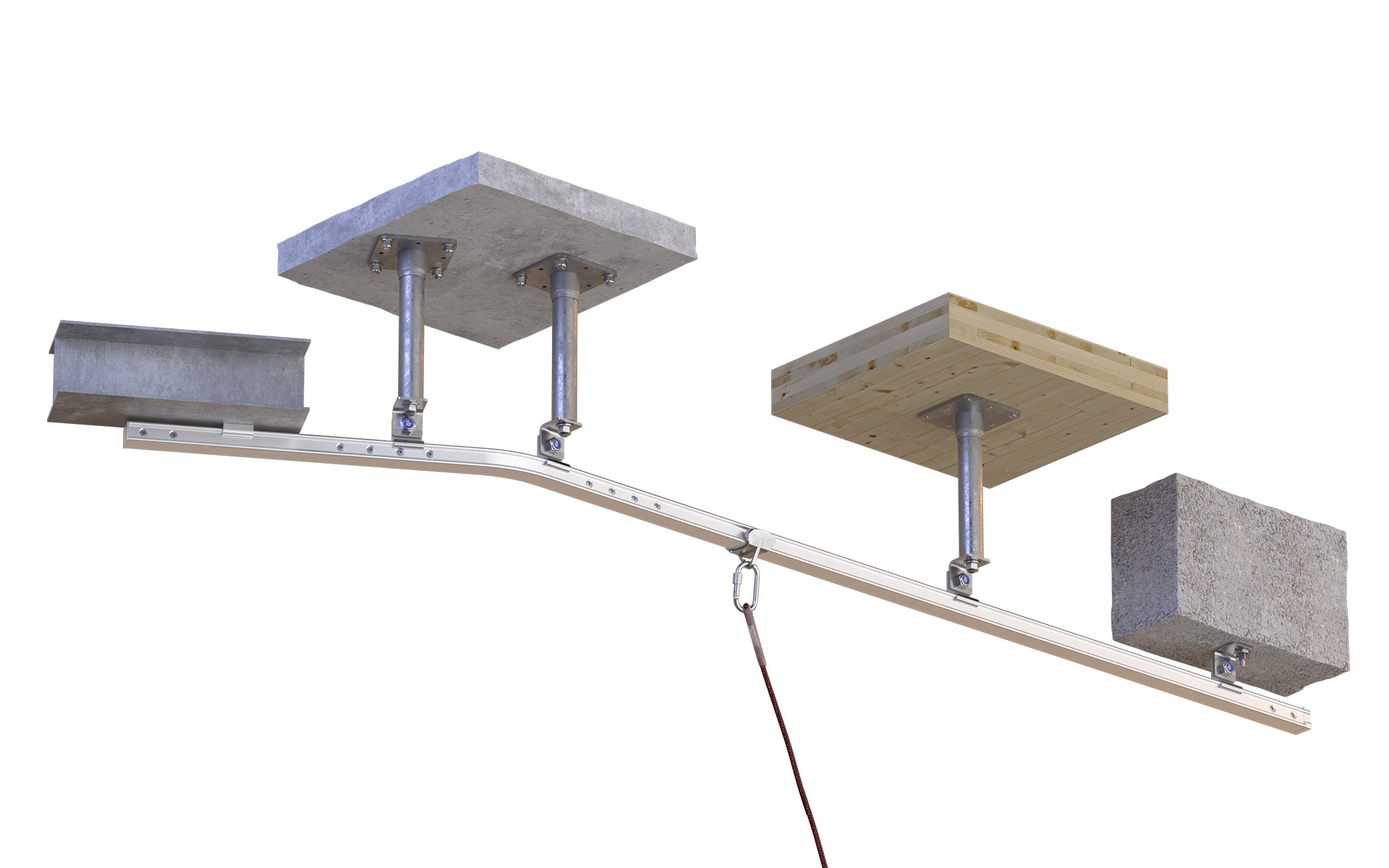

H-RAIL OVERHEAD, overhead rail system

The aerial application of the rail allows operators to work hands-free and safely. Tested for suspended work for up to four simultaneous users.

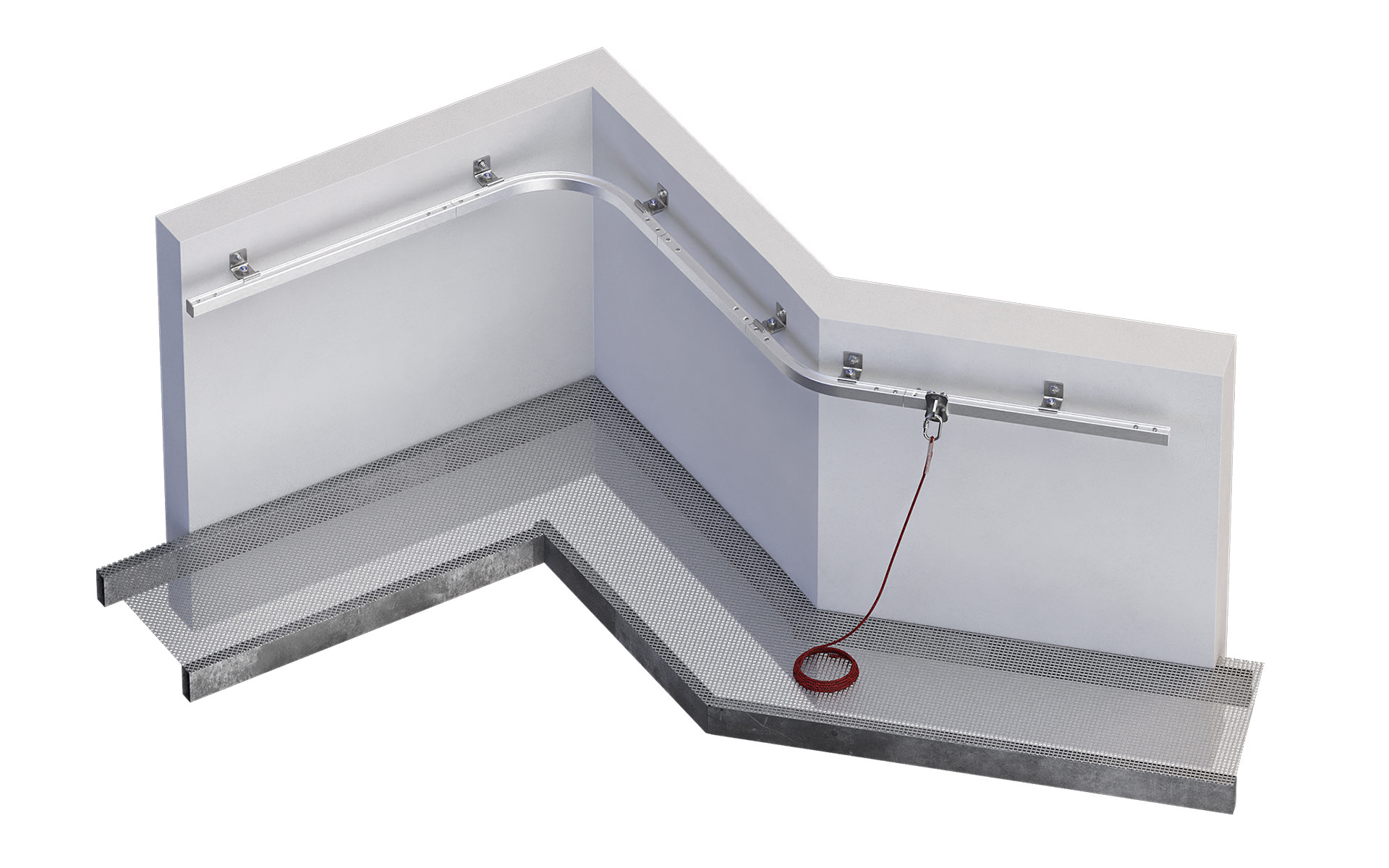

H-RAIL ON WALL, rail system for horizontal wall use

Maximum comfort for fall protection and suspension work thanks to the sliding device with four wheels.

Tested and certified on both traditional materials and glulam and CLT, H-RAIL is the safe and efficient rail system for access and maintenance of roofs and façades of multi-storey buildings.

All rights reserved

Technical Details

- Companies:

- /

- Country:

- Any

- Products:

- H-RAIL + TOWER | TOWER A2 | TOWER XL H-RAIL ON FLOOR H-RAIL ON WALL H-RAIL OVERHEAD